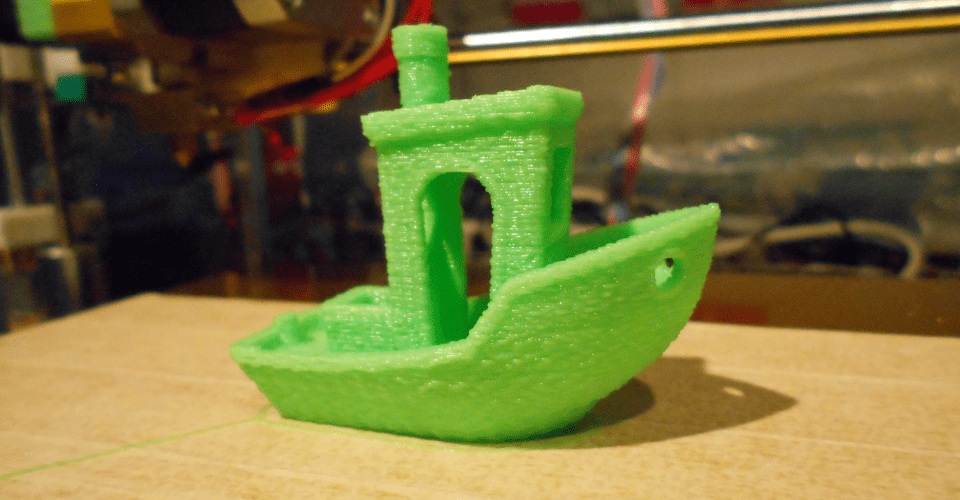

Lots of things can go wrong with your 3D print. The plastic could warp as it cools, your nozzle could get clogged in the middle of printing, or your print can collapse spectacularly under its own weight.

Experienced 3D printing professionals know that these problems are incredibly common – merely a part of the learning process. However, this does not mean that running into problems in the middle of 3D printing isn’t frustrating.

A successful 3D print starts at the bottom. Specifically, you’ll need to make sure that your base layer sticks to the build platform. What are the best ways to solve bed adhesion problems? What could be causing your filament to not stick to the bed? Why is bed adhesion important? A base layer that does not stick completely to the bed or comes off easily will almost inevitably result in a failed print. On the flip […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments