For most individuals or small design firms with digital fabrication needs, an affordable filament-based FDM (fused deposition modeling) machine is going to be the gateway drug into 3D printing.

.

As profits increase, you may step up to an SLA (stereolithography) machine. But here’s the thing: Even if you add an SLA 3D printer, you’re probably not going to get rid of the FDM model. You’ll find it still comes in handy for when you need to, say, quickly crank out multiple parts that don’t require the precision and time of the SLA.

.

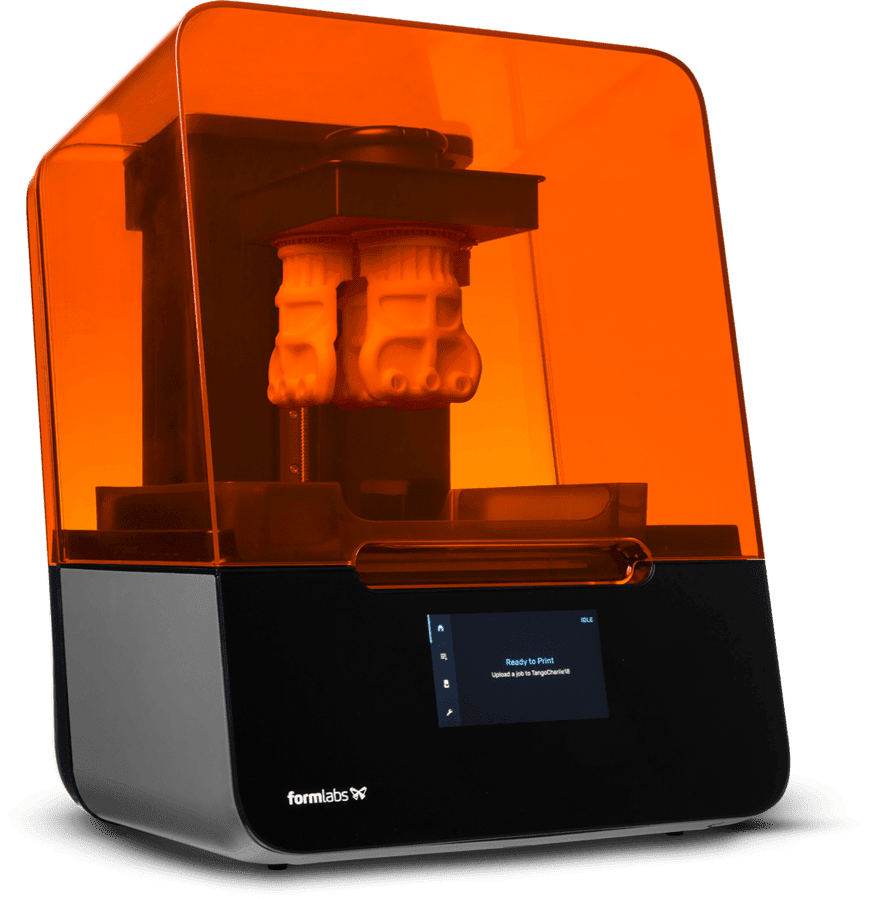

“Many businesses use both FDM and SLA machines alongside one another,” writes FormLabs, who manufactures SLA machines like the Form 3, above. “This opens access to a wider range of applications supported by low-cost rapid prototyping, high quality, functional parts, and comprehensive material formulations.” To make their point–and hopefully a sale–the company’s written up a ” How […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments