In the Star Trek universe, devices called replicators can manifest solid matter in seconds. Thanks to advances in materials science, these science-fiction devices might be closer to reality than we think.

.

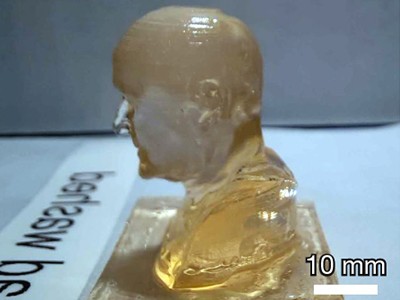

A type of 3D printing called volumetric additive manufacturing (VAM) uses light to rapidly solidify an object in a volume of a liquid precursor. Writing in Nature , Regehly et al. 1 report an advance in VAM that allows solid objects to be printed with a feature resolution of up to 25 micrometres and a solidification rate of up to 55 cubic millimetres per second. The authors call this process xolography because it uses two crossing (x) light beams of different wavelengths to solidify a whole object ( holos is the Greek word for whole).

.

Read the paper: Xolography for linear volumetric 3D printing Conventional 3D printers have gantries that manoeuvre either the printheads or the printed object in three orthogonal directions to orient the printer’s nozzle to the next position to deposit material. However, the fastest 3D printers use light to induce the polymerization of an entire layer of a liquid starting material at a time, thereby allowing solid objects to be drawn out from the […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments