While 3D printing often tends to present itself on the large scale and in spectacular fashion, other times it functions to serve quite ordinary needs. A perfect example would be the fabrication of small but critical parts like clamps.

.

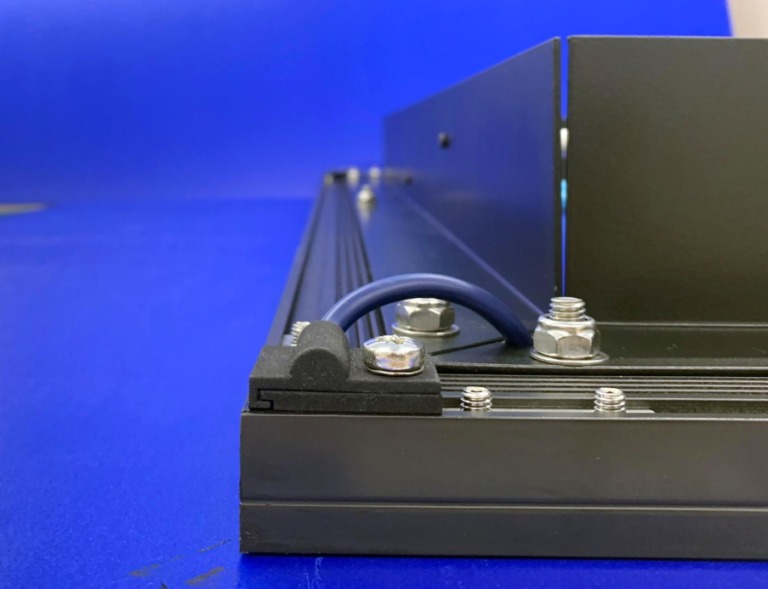

UK-headquartered Spanlite specializes in customized LED lighting and recently found itself in need of interlocking, two-part cable clamps. Before fabrication of the functional part, the company turned to voxeljet UK to create a model of the clamp for testing via high-speed sintering (HSS) with polyamide 12. Harkening back to the most original intent of 3D printing decades ago, companies like voxeljet UK are able to make inexpensive and rapid prototypes. Not only are such parts more affordable, but they also offer the same high performance as those made by traditional techniques, like injection molding. HSS has been in use by voxeljet since 2017 for the production of functional prototypes and […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments