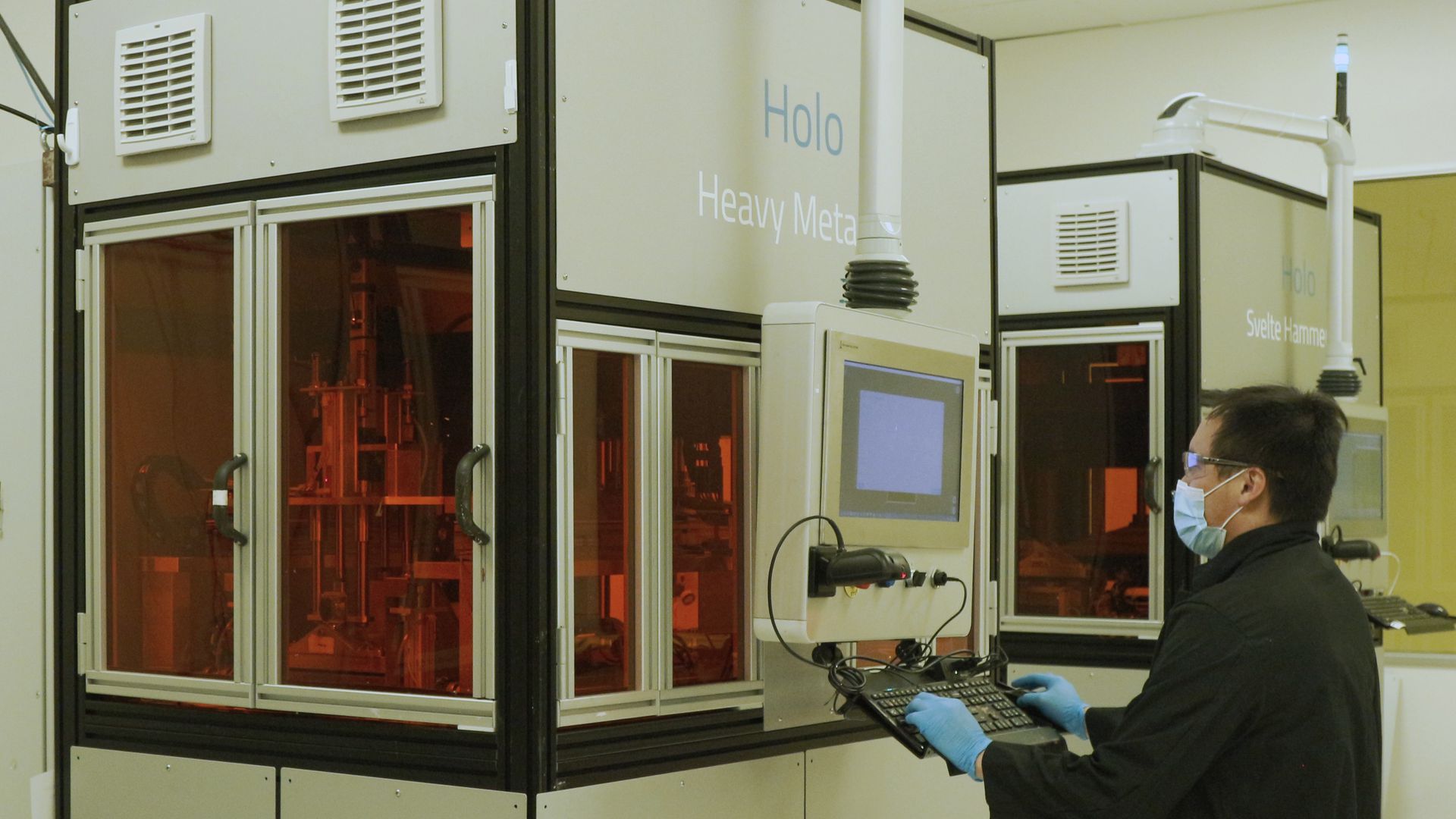

A new generation of heavy-duty 3D printers is increasingly being employed for industrial manufacturing.

.

Why it matters:

3D printers have long been used to speed the making of prototypes, but the growing ability to design and print a range of materials means they are becoming an integral part of the manufacturing chain.How it works:

Manufacturing has historically required the production of parts first by injection molding, which can “take weeks or even months,” depending on supply chains, said Richard Garrity, the CEO of Stratasys, the global leader in 3D printing. Newer generations of 3D printers can enable manufacturers to “skip that process and go right to the end output itself,” he adds, allowing companies to simply mass print the parts they need..

When GM suddenly needed to make ventilators during the early stages of the pandemic last year, 3D printing — also known as additive manufacturing — allowed the company to rapidly transition its automobile assembly lines for the new product. Background: This kind of industrial use marks a change in how 3D printing was initially envisioned, says Bradley Rothenberg, CEO of the 3D printing software company nTopology. “Everyone was […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments