No matter how technologies change, or what new innovations break into the mainstream, the basic goals of manufacturing remain the same: Reduce unplanned downtime, reduce costs, eliminate unnecessary waste, etc.

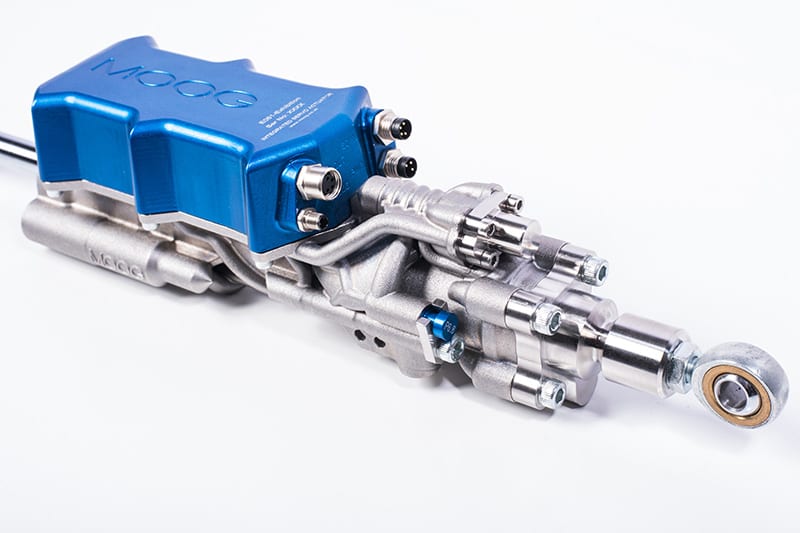

How fortunate it is that 3D printing (a.k.a. additive manufacturing) is one of those cool, innovative technologies that is finding itself a very nice spot in the realm of day-to-day cost and time savings. Not only can it be used to produce interesting and previously impossible designs, it has also become a useful way to change spare parts management.

When a system goes down, making the repairs needed to get it back up and running can be time-consuming. Even more so if the part that needs replacing is no longer readily available. With the right program in place, additive manufacturing can build that part on demand—whether through reverse engineering, digital files from the component supplier, or perhaps through the […]

Click here to view original web page at www.automationworld.com

0 Comments