Gaurav Manchanda, director of healthcare at Formlabs, explains why the future of medicine relies on a responsive, flexible, and agile healthcare system, and how biocompatible materials help get us there.

.

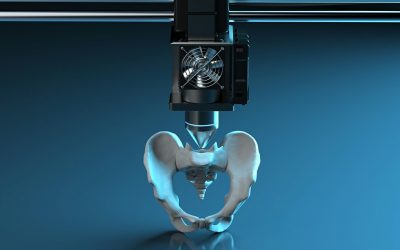

Over the past six months, 3D printing proved its value by producing in-demand medical supplies like PPE and COVID-19 test swabs. The responsiveness of the industry alleviated some of the major shortages the healthcare community faced in the fight against COVID-19. The scalability and versatility of the technology will continue to serve the healthcare industry long after the pandemic ends. Part of the long-term staying power of the technology is its ability to print with biocompatible materials – plastics that can interact safely with the human body. Resins that are produced in ISO 13485 certified and FDA-registered facilities, and tested for biocompatibility and sterilisation compatibility can enable hospitals to reduce risk and increase agility in the medical supply chain while improving patient care for years to come. How biocompatible materials are being used today Implant Moulds: Surgeons and radiologists at University of Michigan printed sterilisable 3D printed moulds to customise the shape of commercially available absorbable orbital implants. Surgical repair of an isolated orbital fracture requires anatomically accurate implant […]

Click here to view original web page at www.med-technews.com

0 Comments