Historically, manufacturers and online retail companies have been forced to limit customization options based on quantity and scale.

.

To produce an original design or custom option, manufacturers would need to produce a new mold, or set up large-scale equipment; if they only produced one item, they wouldn’t generate enough revenue to make up for those high initial costs. Accordingly, they demanded minimum quantities in their run.

.

Customers who wanted something truly unique would have two options: pay out the nose for a single, customized item, or commit to buying at least 100 (or 1,000). And businesses didn’t have much flexibility–they could only offer customization to individual customers, at a small scale, if they could offer it at all.

.

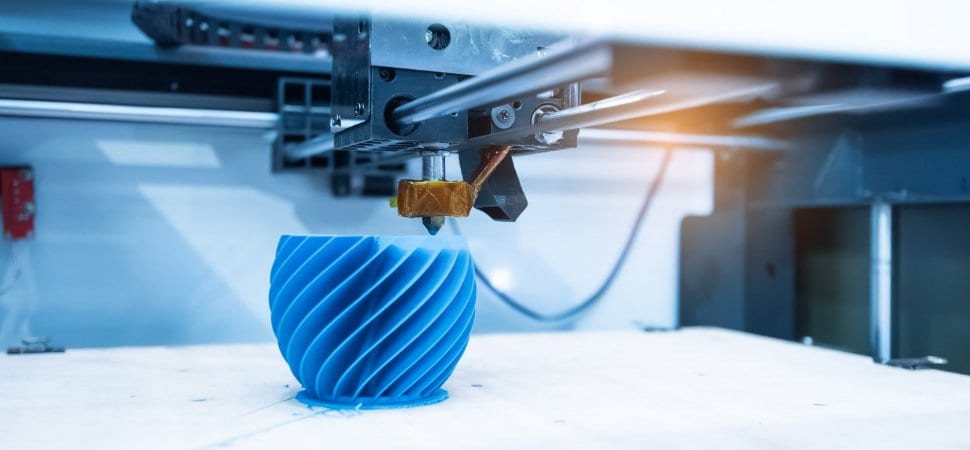

Two technologies are changing this landscape, allowing online retailers and manufacturers to offer customization options to customers at scale: CAD Software and 3D printing. How CAD Software and 3D Printing Work […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments