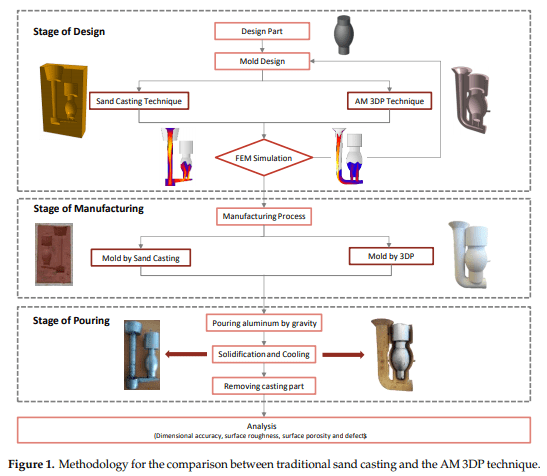

Aluminum alloys feature low density, as well as good corrosion resistance and mechanical properties, which is why casting them is an oft-used manufacturing technique. But, defects in molded parts is still an issue. A team of researchers from the University of León published a paper about their work performing a comparative analysis between producing aluminum parts using a 3D printed mold versus the traditional sand casting method.

.

In sand casting, molds are created by compacting sand around a pattern in a mold box; then, the pattern is pulled out and a cavity in its shape is left. Molten metal is then poured into the cavity to produce components. Reducing porosity, improving the microstructure, and controlling dimensional quality and defects are the three most common issues in casting, but using a properly designed mold can help. “The manufacturing cost of a mould with complex geometry is one of […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments