Advances in developing composites for additive manufacturing have accelerated in the last few years, with increasing research and innovation in both, desktop and industrial AM using composites, using chopped or continuous fiber technology, with carbon fibers or nanotubes, or glass fibers most typically used for reinforcement.

.

3D printed composite materials and sandwich structures (lightweight core sandwiched by thin face sheets) have been the subject of increasing research at universities and national laboratories. But the focus has been more on studying compressive failure, load-carrying capacity, ductility, morphology, tensile or friction properties.

.

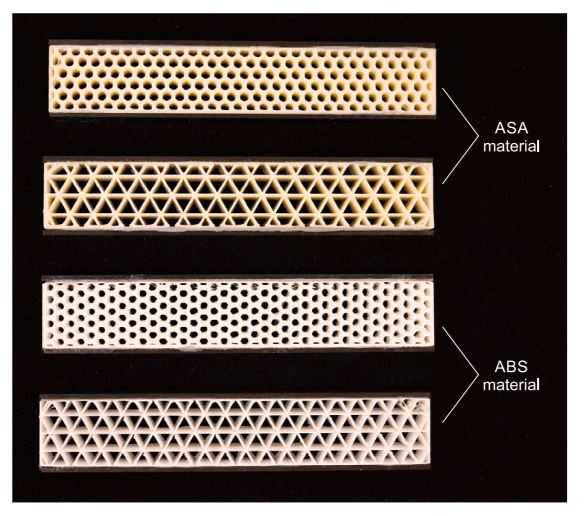

This study, published in the Polymer Testing Journal , is a collaboration between researchers at Deakin University (Australia) and University of Siegen (Germany), and the focus was to investigate the impact to performance or properties in 3D printed composite (specifically cores) structures caused by accelerated thermal aging. The authors chose to focus here due to a lack of investigative […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments