Brent Chanin has always been a tinkerer. After studying mechanical engineering in college and working briefly as a scuba diver in underwater archaeology, he started a consulting company pitched toward helping inventors take their ideas “from a paper napkin to the real world.”

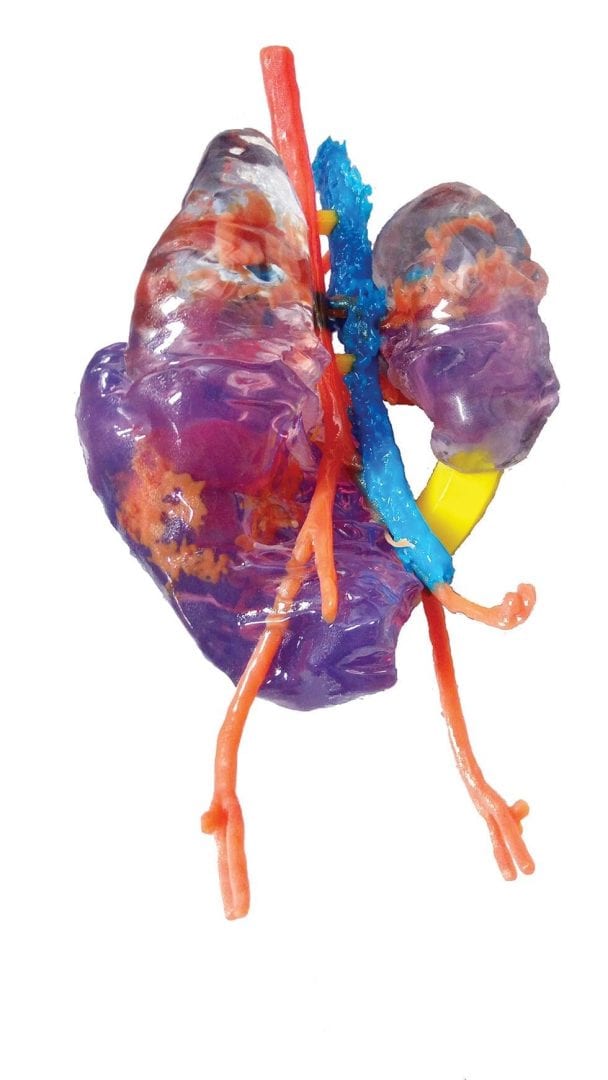

One day, a radiologist from NYU Langone approached Chanin: He had figured out how to turn medical imagery into 3D computer renderings, but he wanted help turning those digital drawings into 3D-printed models that you could hold in your hand. It was a challenge right up Chanin’s alley, and the two partnered for a few years, banging out patient-specific plastic organs on 3D printers and bringing the models to surgeons to see how the technology might help their work.

“It became very clear that this was powerful,” says Chanin. “The first time it really clicked for me was when we gave a neurosurgeon a 3D-printed […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments