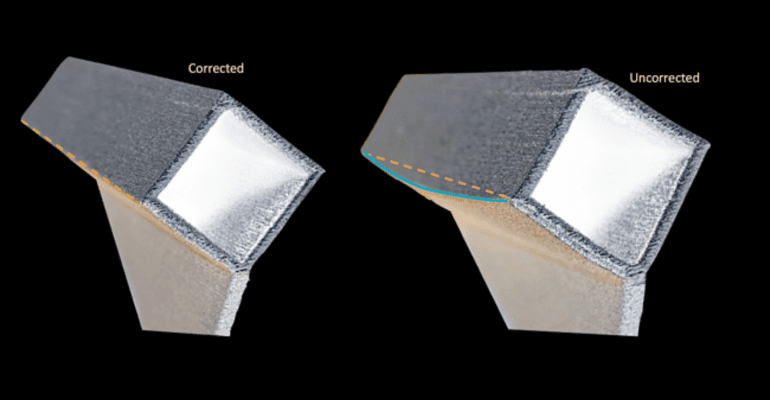

Software accurately predicts deformations due to 3D printing and adjusts the part’s design to compensate for it.

.

In 3D printing (aka additive manufacturing or AM) there are countless ways things can go wrong and only one way they can go right. This is doubly true on the first print of a part, when the engineer finds out if what looked good in the plans holds up as a physical object.

.

Mistakes that are only revealed after 3D printing is done can sink investments in time and capital. Persistent issues can even hamper creativity as they incentivize engineers to build “safe” parts that print successfully, even if they aren’t fully optimized.

.

By solving predictable issues, we can reliably produce more complex parts and let engineers design the best parts for the best performance. To build confidence in 3D metal printing, we need to increase the accuracy of first-article prints. The […]

Click here to view original web page at www.machinedesign.com

0 Comments