Researchers İlke Demir, Daniel G. Aliaga, and Bedrich Benes tackle one of the most popular topics in 3D printing today: optimization. While the many benefits of digital fabrication are oft discussed—from greater affordability, improved speed in production, and the ability to create and re-design without a middleman—challenges continue to arise due to continual innovation. Ever on the search for perfection, users are continually seeking ways to predict mechanical properties, decrease defects, and monitor additive manufacturing systems.

.

In this study, the authors focus on reducing the amount of material used, reducing print times, and refining accuracy.

.

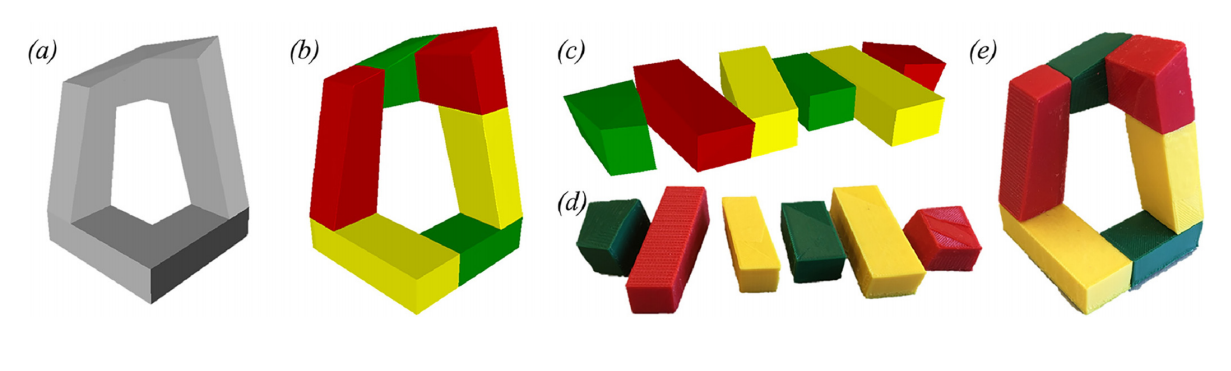

Detailing the efforts of their research in ‘ Near-convex decomposition and layering for efficient 3D printing ,’ we learn more about their ‘divide-and-conquer approach,’ featuring automatic decomposition and configuration of an input object into print-ready components.

.

“3D printers have both limitations and advantages depending on the coherency between the printer features and […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments