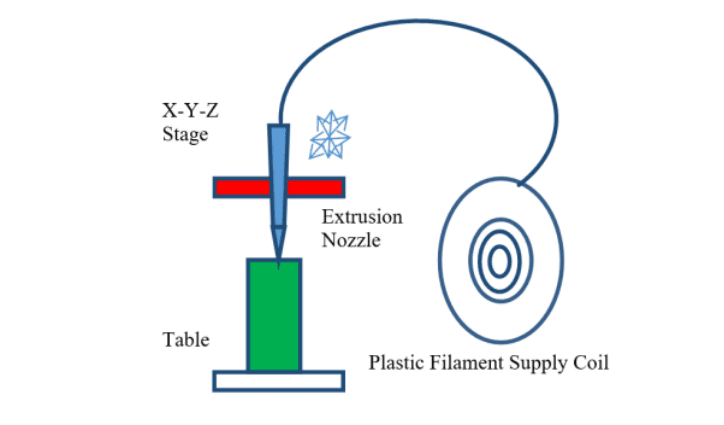

In ‘ Comparative Study and Measurement of Form Errors for the Component Printed by FDM and PolyJet Process ,’ authors Nagendra Kumar Maurya, Vikas Rastogi, and Pushpendra Singh (all researchers from India) explore the differences between FDM 3D printing and polyjet 3D printing—for the purposes of rapid prototyping.

.

For the fused deposition modeling (FDM) system, testing was performed on both an Ultimaker 2 and a MakerBot Replicator 2 . For polyjet, the Objet30 (manufactured by Stratasys ) was used. “CATIA-V6 was used for the 3D modeling and a coordinate measuring machine (CMM) was employed for the measurements of dimensions.

.

Optical profilometer was considered to measure the surface roughness of component. ISO UNI EN 20286-I (1995) and DIN 16901 standards was used for the evaluating IT grades for each selected dimension,” explained the researchers. Fused deposition modeling system PolyJet 3D Printing system A sample automotive connecting rod was created on […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments