One of the greatest benefits that 3D printing can offer in the fabrication of high-performance parts is speed. Users around the world continue to improve on this, reveling in both the ability to innovate like never before—as well as the rewards of cutting out the middlemen in manufacturing and tossing aside the reliance on traditional technology.

.

This means that parts can be made exponentially faster.

.

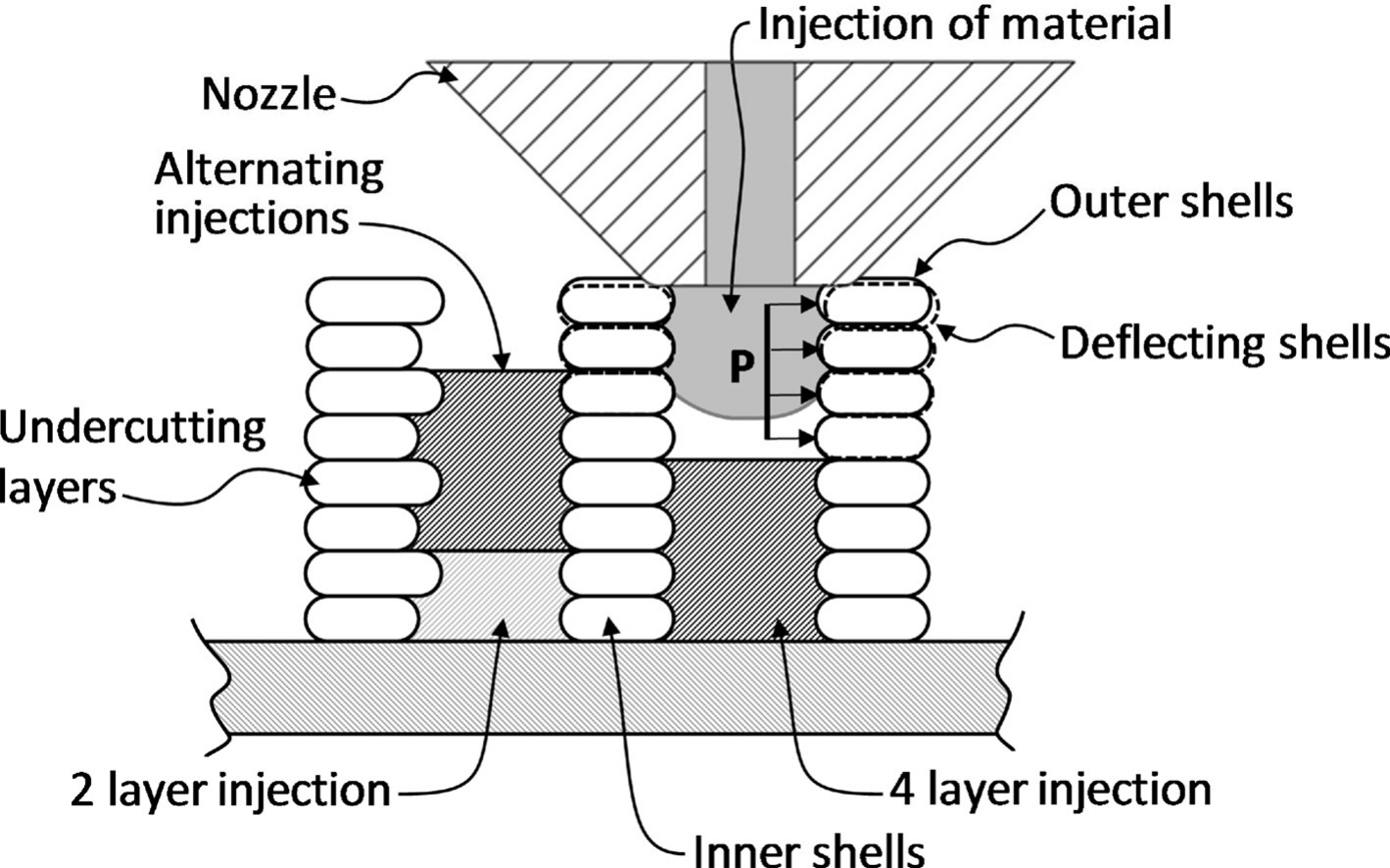

Conventional technology has not gone by the wayside whatsoever though and may be used with 3D printing or other hybrid technologies. Companies like Denmark’s Addifab have been hailed for new methods like freeform injection molding (FIM) , printing cavity inserts with resin, and then filling them with materials like PEEK, metal, and more. Meanwhile, other startups like Tennessee-based Collider have created the hybrid Orchid 3D printer for a similar process called Programmable Tooling. With digital light processing (DLP), they create molds that are […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments