Researchers from France and the UK are delving into 3D printing in construction and experimenting with parameters in materials.

.

Releasing their findings in ‘ Rheological properties of 3D printing concrete containing sisal fibres ,’ the authors explain positive and negative effects as they studied impacts on cement.

.

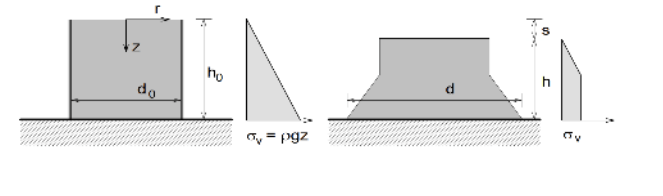

Formworks are a major factor in the cost of concrete construction today, so the benefits intrinsic to 3D printing such as greater affordability overall, rapid speed, customization, and more make the technology enticing to industrial users. Currently, the most popular methods used are D-shape or binder jetting, and concrete printing via extrusion. For this study, the researchers used fly ash and limestone powder as a binder with Portland cement, and investigated the following for impacts on the printable mortar: Fly ash Limestone powder (LS) Percentage of natural sisal fibers (NF) Dosage of superplasticizer (SP) Viscosity modifying admixture “The rheological parameters were evaluated […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments