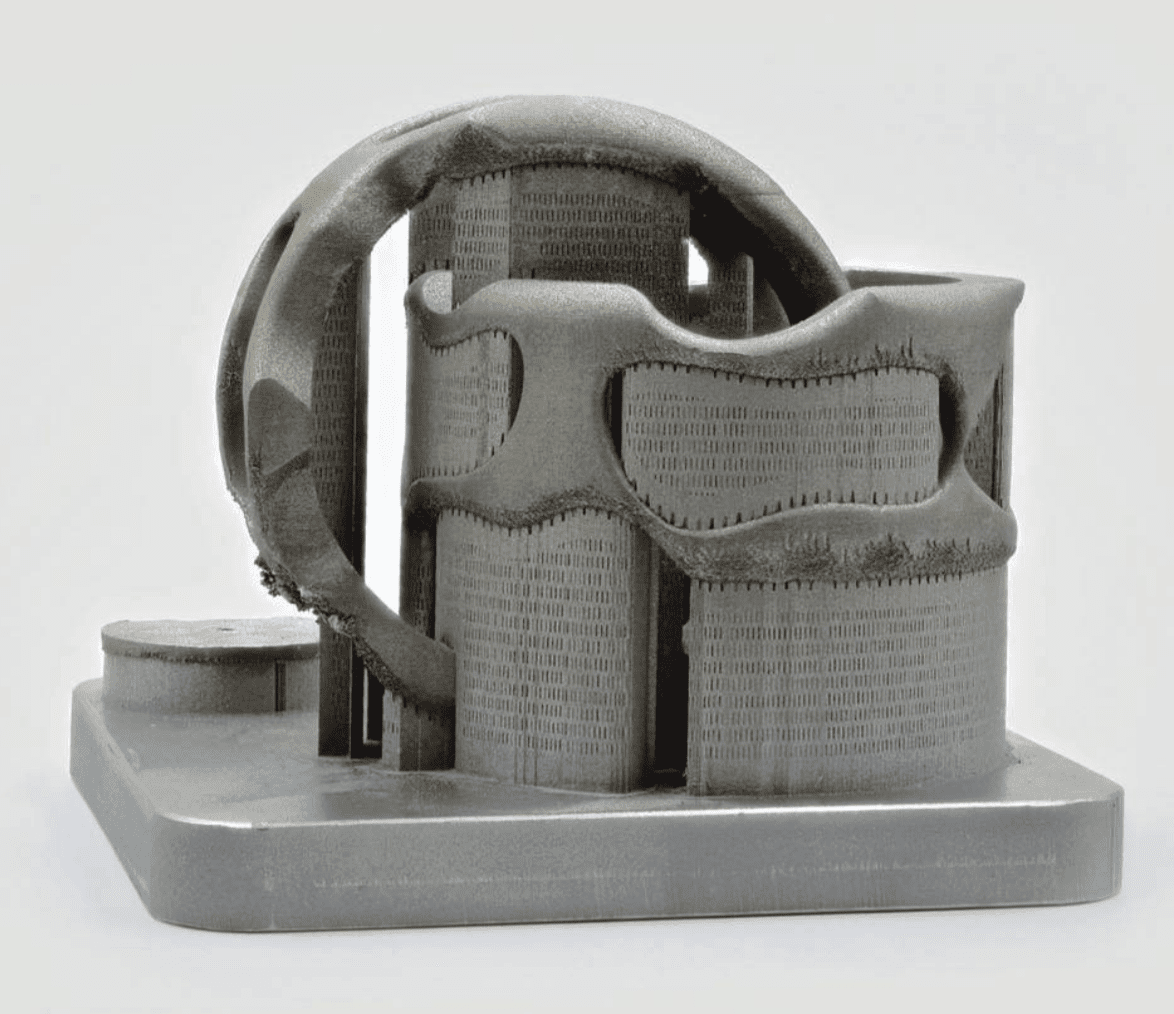

A friend tipped me about Owen Hildreth’s work. The Colorado School of Mines Professor has spent years developing an automated metal support removal process for metal printing.

.

This is the holy grail of metal 3D printing. Direct Metal Laser Sintering (PBF) have a huge problem which is that they need support structures to manage thermal stress in the part. These supports are made of metal so have to be cut off by hand. Then the evidence of these supports often has to be filed down manually. This is a significant cost component of metal 3D printing, around two thirds to a third. Manual support removal also introduces the human element into an automated process increasing possible variability and errors.

.

Automated support removal will enable a huge amount of new business cases to emerge for 3D printing. Ping pong ball parts could become softball-sized parts opening up a lot […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments