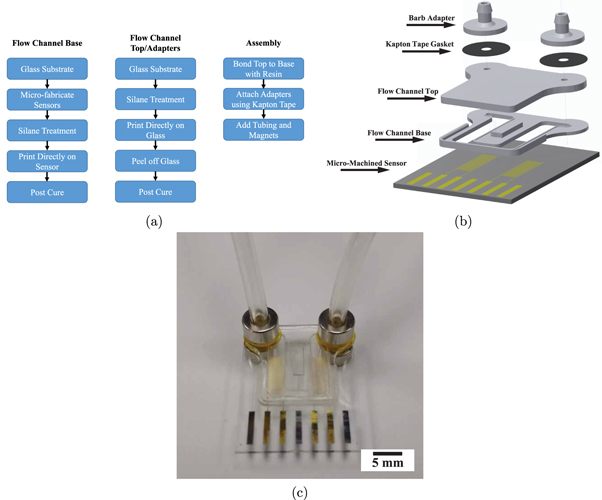

As MSU has continued to stand strong in research, I was especially interested to see that more news has emerged regarding their work in 3D printing for microfluidics. This is an area of science that we follow often, but in this particular work, the researchers have created a unique method, 3D printing tiny liquid-filled channels onto glass (allowing them to view the microfluidics with a microscope).

.

Not only does 3D printing allow the researchers to enjoy most of the classic benefits of 3D printing—to include customization on-demand, fabrication on-site in the lab, and greater affordability—but they will also be able to translate this work for use in applications like sensors used to detect and measure minerals in water. Stephan Warnat, assistant professor in the Department of Mechanical and Industrial Engineering in MSU’s Norm Asbjornson College of Engineering, will be using the technology to create micro-sensors to evaluate water quality.

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments