International researchers have created a novel framework for strengthening 3D prints by aligning filaments, detailing their study in the recently published “ Reinforced FDM: Multi-Axis Filament Alignment with Controlled Anisotropic Strength .”

.

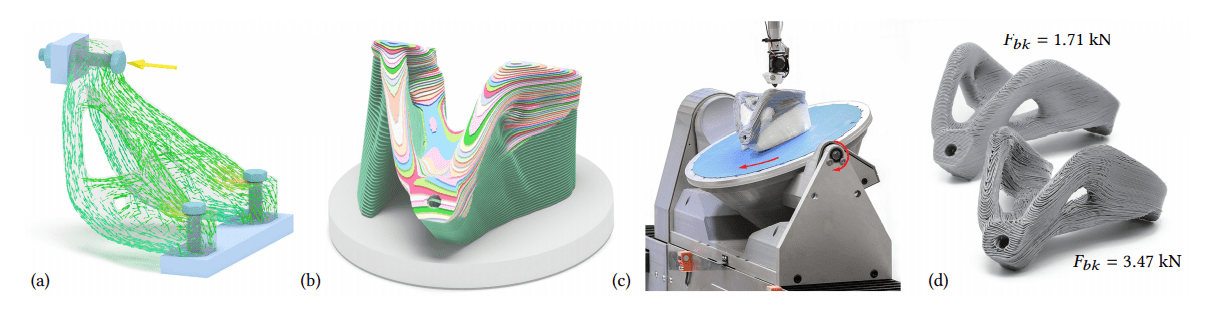

As has long been shown, anistropy is typically a weakness of 3D printing, particularly in fused deposition modeling processes. Due to the relative weakness of inter-layer bonding, the Z-axis is much weaker than the X and Y axes. In the case of this research, however, anisotropy is actually used to improve the strength of 3D printed objects by over two times. This is in contrast to more conventional methods typically used for strengthening parts such as modifying geometry, optimizing parameters like printing orientation or infill percentage and structure, or performing post-treatment processing via thermal or chemical features. This research uses the new framework to take advantage of the anisotropy, creating “field-based optimization” for fabricating curved layers (and […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments