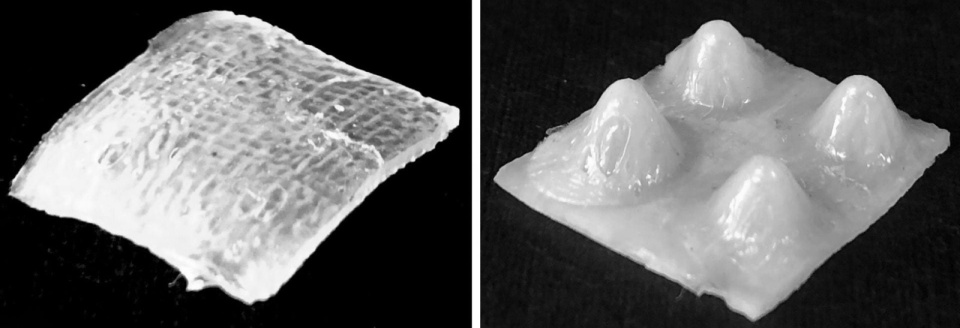

It just got a little easier to create soft robots that adapt to the world around them. Rice University researchers have developed a 3D printing technique (they call it “4D”) for material that automatically changes to an alternate shape when subjected to an electric current, changes in temperature or simple stress.

.

The team produced a liquid crystal polymer ‘ink’ with two exclusive sets of molecular links — one with the originally printed shape, and another by manipulating the material. In this case, scientists just had to heat or cool the material to flip it between a flat surface and a bumpy one, among other changes. The challenge was to craft a polymer mix that could be printed in a catalyst bath without losing its shape, Rice said. There are drawbacks. You can’t print unsupported structures, and that limits the shape combinations you can make. There’s also no immediate indication […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments