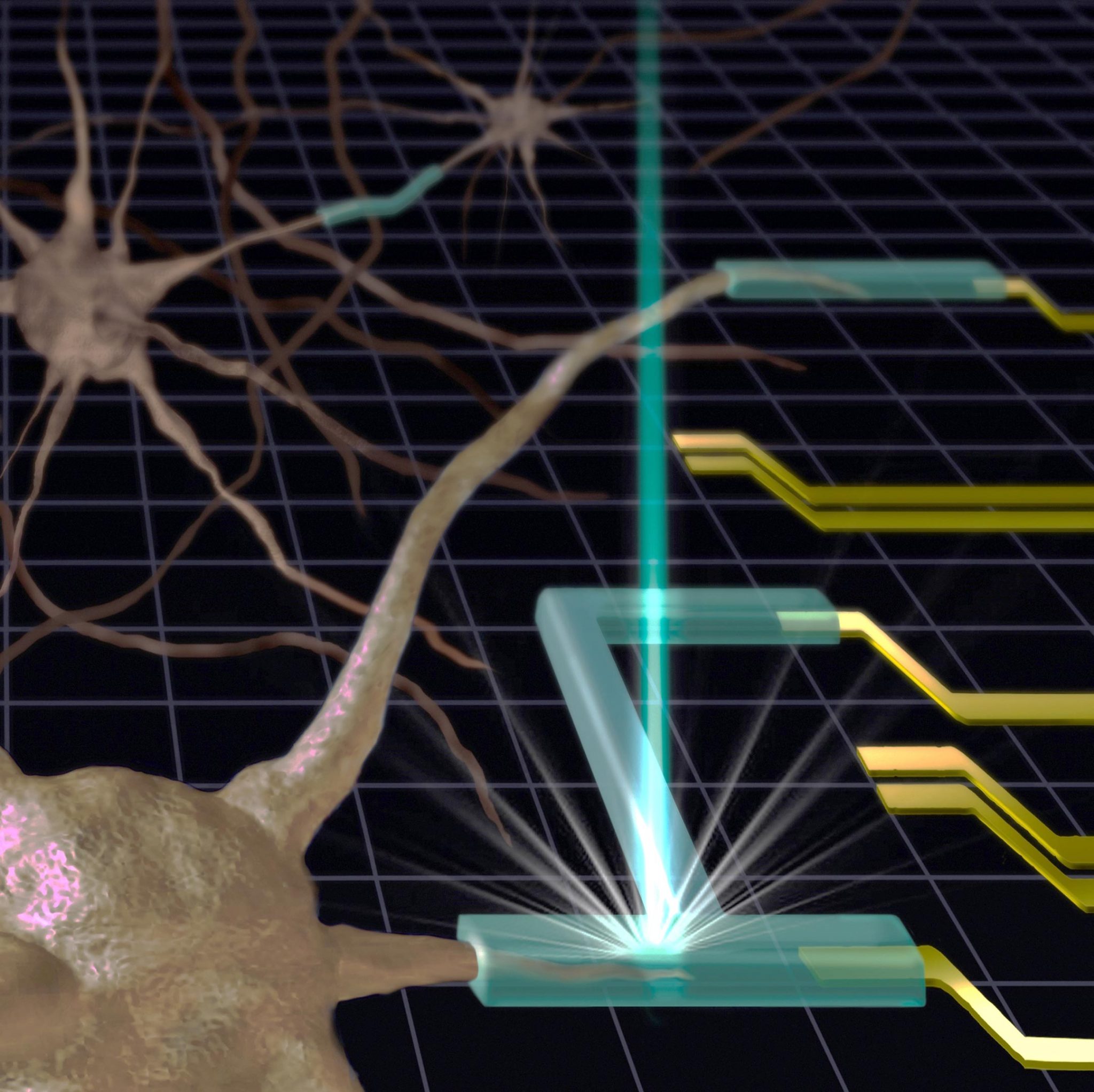

Illustration of a prospective biocompatible interface shows that hydrogels (green tubing), which can be generated by an electron or X-ray beam 3D-printing process, act as artificial synapses or junctions, connecting neurons (brown) to electrodes (yellow).

.

Researchers at the National Institute of Standards and Technology (NIST) have developed a new method of 3D-printing gels and other soft materials. Published in a new paper, it has the potential to create complex structures with nanometer-scale precision.

.

Because many gels are compatible with living cells, the new method could jump-start the production of soft tiny medical devices such as drug delivery systems or flexible electrodes that can be inserted into the human body. A standard 3D printer makes solid structures by creating sheets of material — typically plastic or rubber — and building them up layer by layer, like a lasagna, until the entire object is created. Using a 3D […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments