A Quick Fix

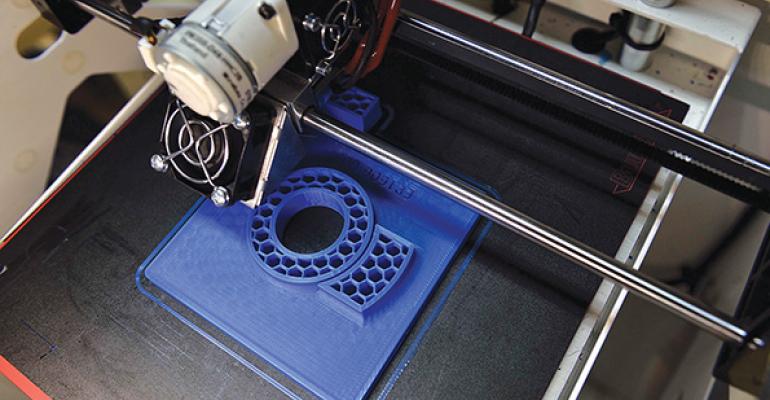

Amid all the excitement about the potential of additive manufacturing (AM) in the aftermarket, today’s applications are often quite prosaic. Plastic air vents, window breather pipes and video-monitor shrouds are understandable starting points for MRO companies familiarizing themselves with the technology, but they are unlikely to persuade that 3D printing will transform the industry anytime soon.

Of course, much bigger developments are underway at aircraft and engine manufacturers, which are investing billions in AM and have already begun producing some metal components. Examples include fuel nozzles for the CFM Leap engine and a 1.5-m-wide (4.9-ft.) front-bearing housing for the Rolls-Royce Trent XWB engine. In principle, the metal printing process is very similar to that used by MROs to produce plastic cabin parts, but metallic AM components can exhibit lower static and fatigue strengths than rolled billets of metal. Overcoming such challenges requires considerable investment […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments