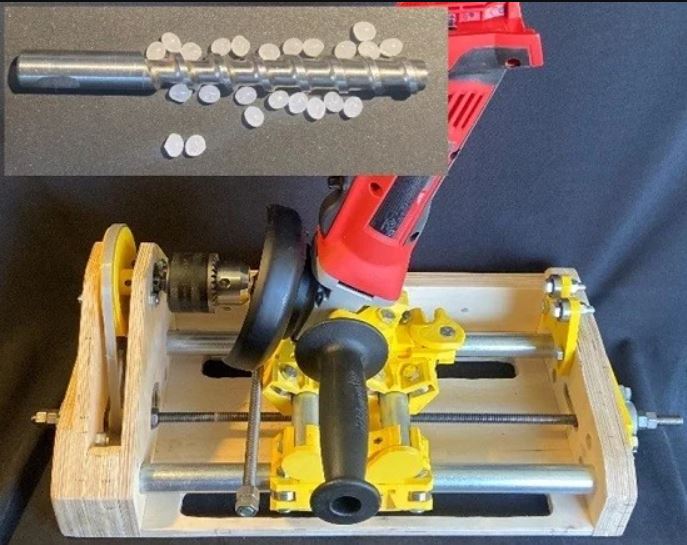

In pursuing the Distributed Recycling and Additive Manufacturing (DRAM) approach to open-source hardware development, a significant challenge lies in addressing the high cost of the compression screw component for alternative 3D printers, such as Fused Particle Fabrication (FPF) or Fused Granular Fabrication (FGF).

.

Platform solutions such as RepRap and Arduino, have allowed users and professionals worldwide to access or manufacture products or scientific tools themselves, cheaper and more effectively than commercial hardware products.

.

Yet, as Dr. Joshua Pearce, of Michigan Technological University (MTU), notes in his study on the topic, open hardware lags the success of the open software community by about fifteen years. It is initiatives such as Dr Pearce’s Open Lab that are helping to bridge this gap—and in this case, with open hardware solutions that make FPF and FGF cheaper, more accessible, and more efficient than they are at present. The details of the lab’s work […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments