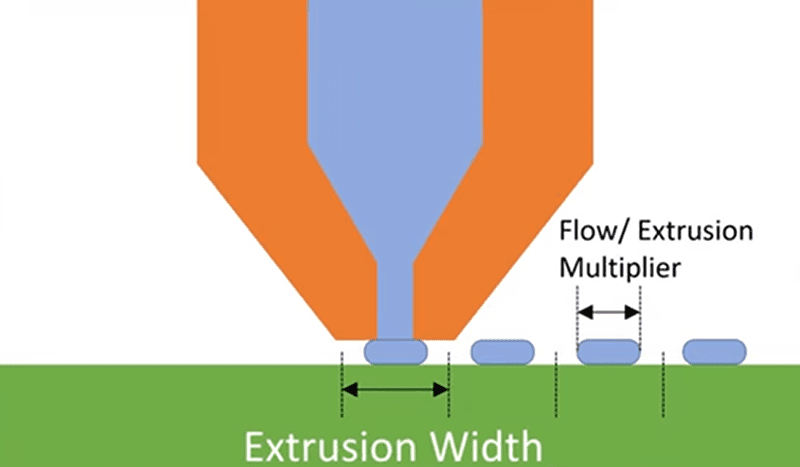

When you 3D print something, you probably adjust the layer height based on your desired print quality. Speed is another parameter that many people adjust. But what about extrusion width?

.

The parameter is there, but most people leave it at the defaults. [Stephan] wondered about it, and after running some tests , made a video you can see below trying to determine if it affected strength and print quality. The tests were pretty straightforward. Some Benchys and other test pieces at each setting were observed and — in some cases — destroyed. He ranged the width from 90% to 250% of a 0.4mm nozzle.

.

Important to note, his results are from a nozzle that has a flat lip around the aperture. If yours doesn’t look like that, you will see different results. Until he went to 140%, the appearance of the Benchy test print looked good. Once he got […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments