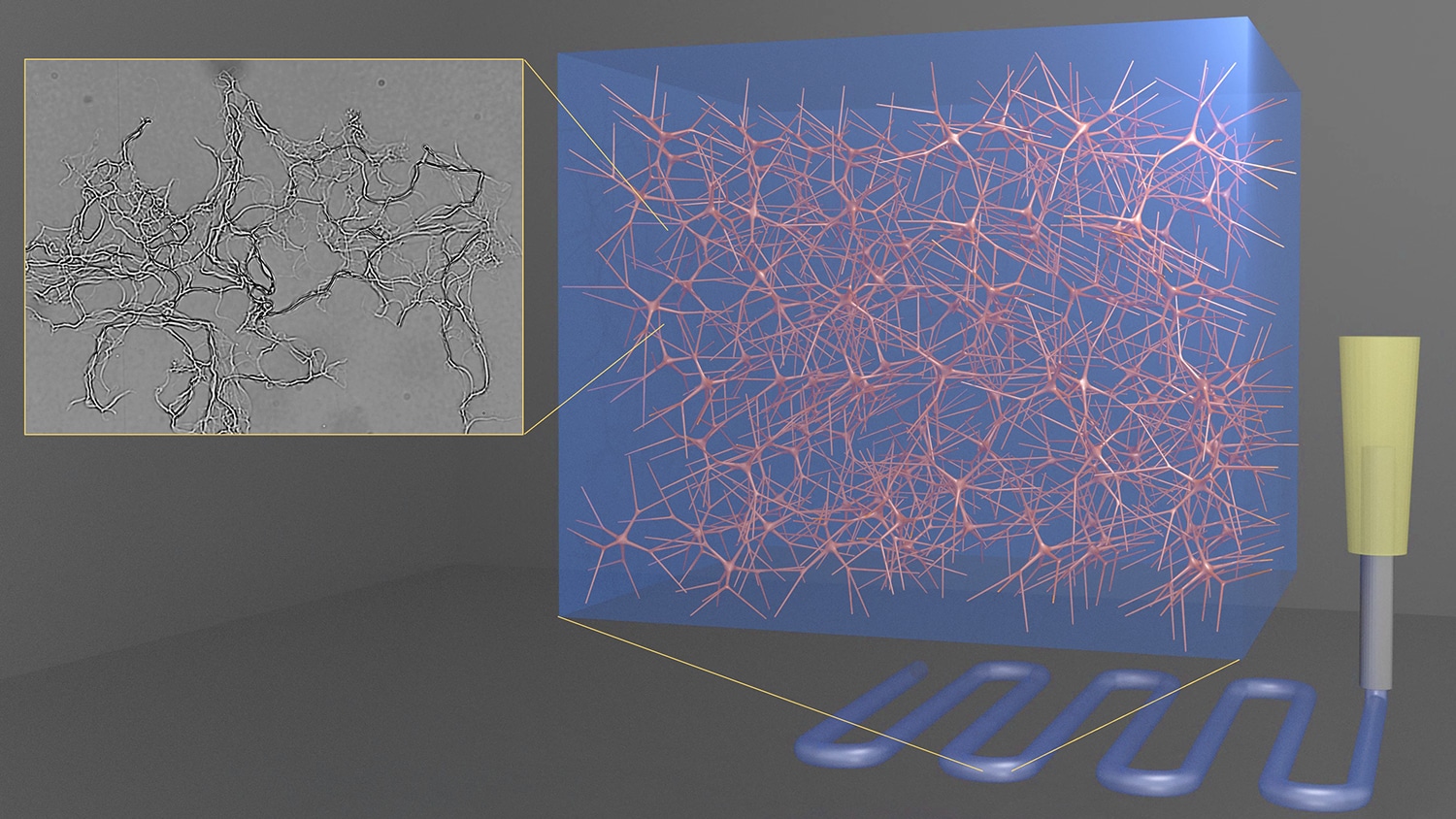

3D-printable gels with improved and highly controlled properties can be created by merging micro- and nano-sized networks of the same materials harnessed from seaweed, according to new research from North Carolina State University. T

.

he findings could have applications in biomedical materials – think of biological scaffolds for growing cells – and soft robotics. Described in the journal Nature Communications , the findings show that these water-based gels – called homocomposite hydrogels – are both strong and flexible. They are composed of alginates – chemical compounds found in seaweed and algae that are commonly used as thickening agents and in wound dressings. Merging different-size scale networks of the same alginate together eliminates the fragility that can sometimes occur when differing materials are merged together in a hydrogel, says Orlin Velev, S. Frank and Doris Culberson Distinguished Professor of Chemical and Biomolecular Engineering at NC State and corresponding author of the paper. “Water-based materials can be soft and brittle,” he said. “But these homocomposite materials – soft […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments