Researchers at the University of California at Santa Barbara have detailed a method of 3D printing soft, elastic materials — resembling human skin in their mechanical properties — at room temperatures and without solvents.

.

“We start with long polymers that are not crosslinked,” explains first author Renxuan Xie of the team’s work. “That allows them to flow like a fluid. But, after you shine the light on them, the small molecules between the polymer chains react and are linked together into a network, so you have a solid, an elastomer that, when stretched, will return to its original shape.”

.

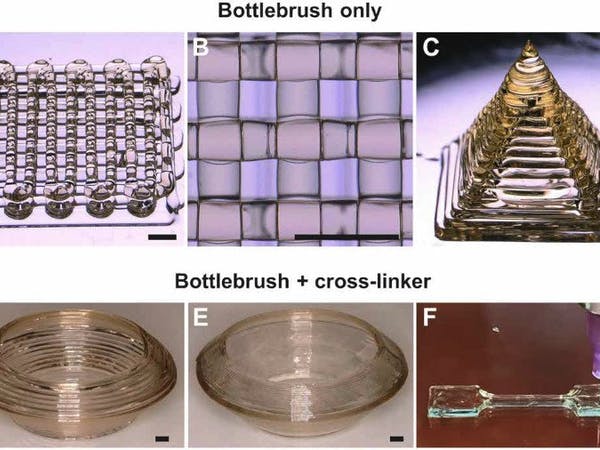

The approach involves self-assembling bottlebrush polymers, which begin as a soft butter-like solid but liquefy under sufficient pressure — making them suitable for use in a 3D printer using direct ink writing (DIW). Post-printing, the material is exposed to ultraviolet light — transforming it into a permanent solid with a softness similar to that of human skin. Printed at a low temperature, the clever material requires no solvents and should be bio-compatible.

.

“The modulus of our material is a thousand times smaller than that of a rubber band,” Xie notes. “It is super-soft — it feels […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments