In the recently published ‘ Research on Improving the accuracy of FDM 3D printing process by using a new designed calibrating part ,’ Romanian researchers explore new ways to improve the quality of parts.

.

As there is a substantial shift from the use of 3D printing for rapid prototyping—to using the technology for innovative and functional parts (many of which have never been possible before), users on all levels continue to seek better accuracy for their specific project needs.

.

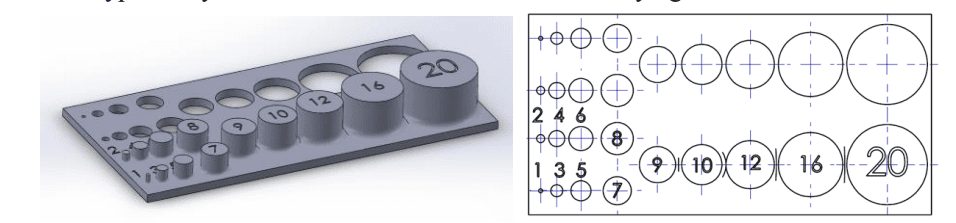

Material plays a large role, whether it is ABS or TPU, along with the proper settings—and calibration procedures and parts. In this study, the research team worked to improve FDM 3D printing at the Technical University of Cluj-Napoca through the development of new software and a calibration part. The new part is comprised of a series of cylinders and holes, with a range of diameters from 1-20mm. SolidWorks Simulation was […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments