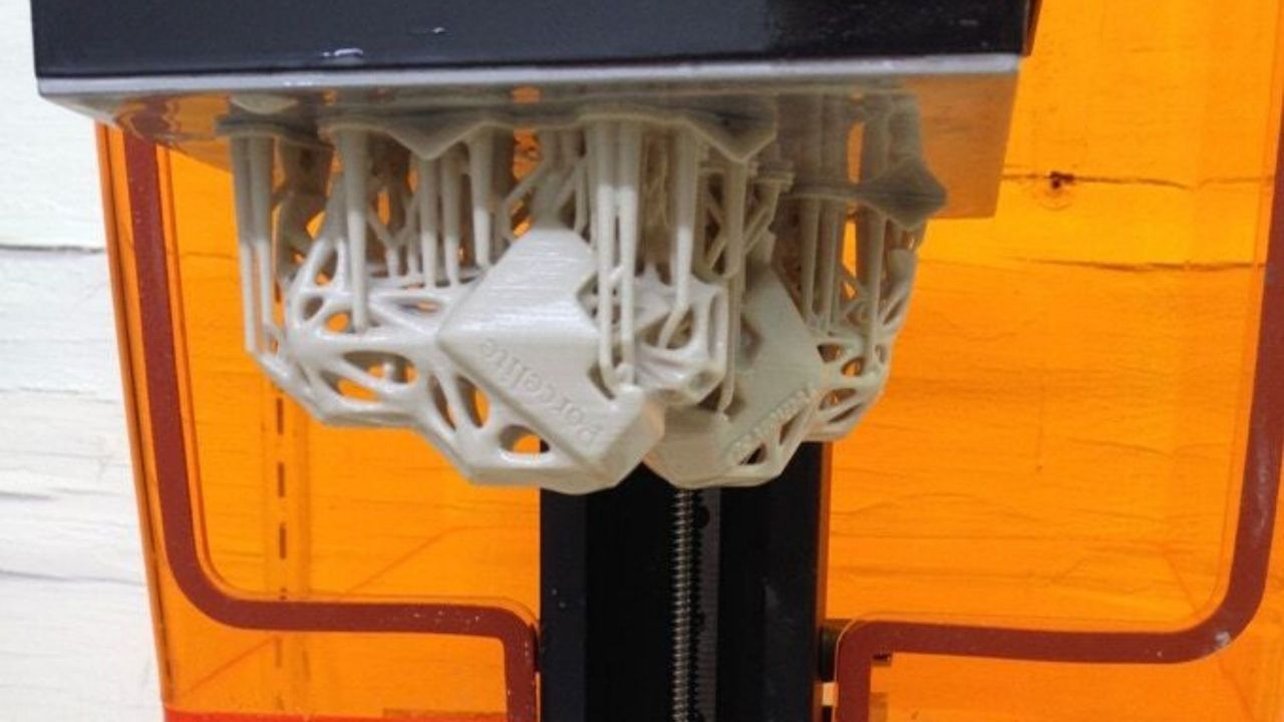

Liquid resin is the main material used in stereolithography (SLA) 3D printing. SLA uses a UV laser that traces the shape of an object onto the surface of a photopolymer vat. The resin then cures to form layers of the print, and the entire process is repeated until it’s a complete 3D print.

.

Using a resin 3D printer is very different from using an FDM printer because of the unique properties of resin itself. Resins used in 3D printing have toxins and need to be safely handled, stored, and disposed of. Not surprisingly, resins’ toxicity makes the whole process of disposal more complex than with FDM and plastic filaments. .

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments