Additive techniques under development can print plastic parts up to 100 times faster than traditional 3D printing approaches

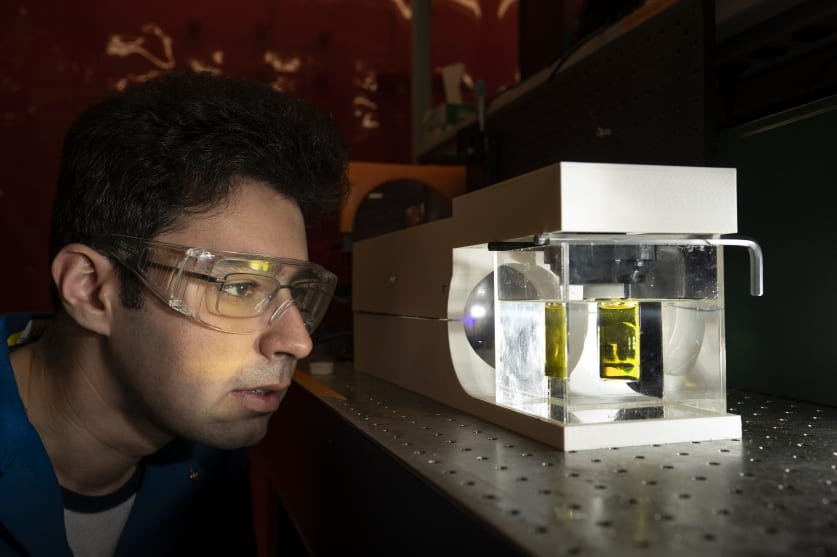

UC Berkeley’s stack-free 3D printer, dubbed the “Replicator,” features an LED light source that shines a series of optimized images into a rotating volume of light-sensitive material. The material solidifies when enough light has been absorbed.

Additive manufacturing (AM) works as its name suggests, by adding material one layer at a time until the workpiece reaches its final shape. The grandfather of all AM systems—the stereolithography apparatus—was invented more than 30 years ago. It uses an ultraviolet light source to cure individual layers of photoreactive resin. Some 3D printers work like a hot-glue gun, squirting out narrow strips of molten polymer in a raster-like pattern. Others use laser light to fuse each layer of metal or plastic to the layer below. Despite the range of 3D printing technologies, all share some […]

Click here to view original web page at www.thefabricator.com

0 Comments