University of Cincinnati grad student Arshad Mohammed doesn’t yet have his master’s in mechanical engineering, but he’s already working on a project that could help the United States Navy all over the world.

.

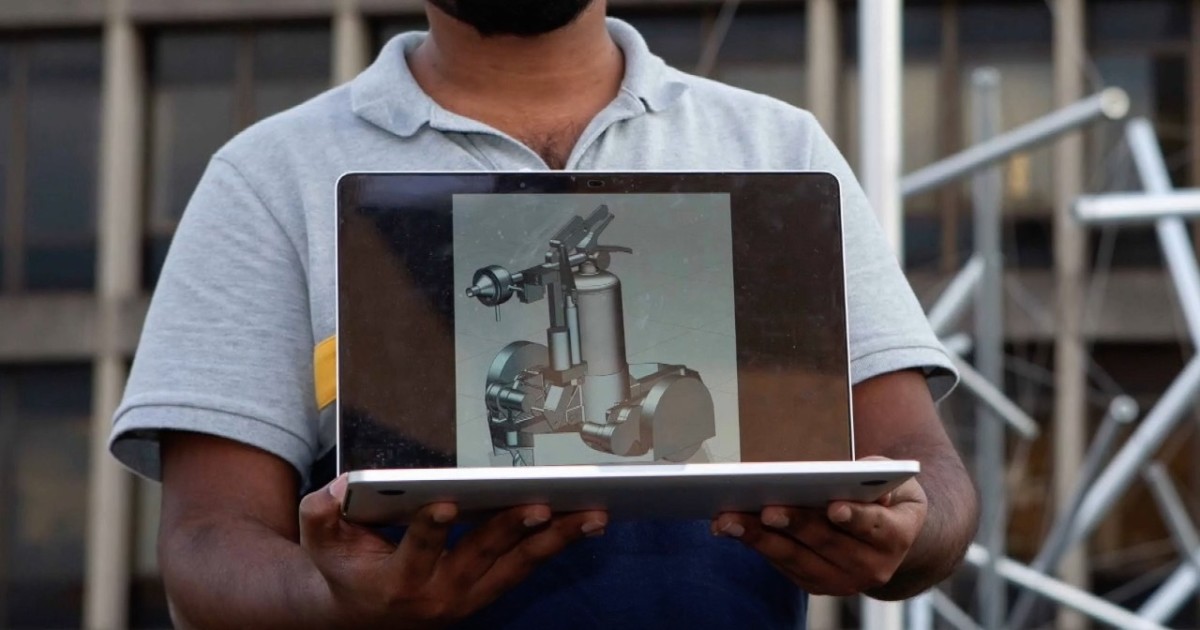

He spent part of his Wednesday afternoon working on a special nozzle meant to help jet engines run more quietly. How does a student get involved in a project with such ambitious scale? 3D printing. Mohammed designs miniature versions of the nozzle on his computer and prints them in the school’s fabrication lab, which allows him to test their effectiveness without spending millions to create a full-sized prototype.

.

“Once the tests are done and the values are efficient, they run the tests on a very large scale,” he said Wednesday. Interest in 3D printing is growing quickly at UC, lab director Sam Antoline said Wednesday evening. It’s been considered a niche technology in the past, but growing awareness and availability means people in 2021 are more likely to consider it as an alternative to traditional manufacturing in situations where specificity is everything. “It is already very integral in aerospace, medical and biomedical, and I can’t imagine any of those areas moving forward without it,” Antoline said. […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments