An article published by Carnegie Mellon University ’s College of Engineering discusses the work of CMU researchers examining the ways keyhole-shaped cavities form in melt pools during metal laser-powder-bed-fusion 3D printing.

.

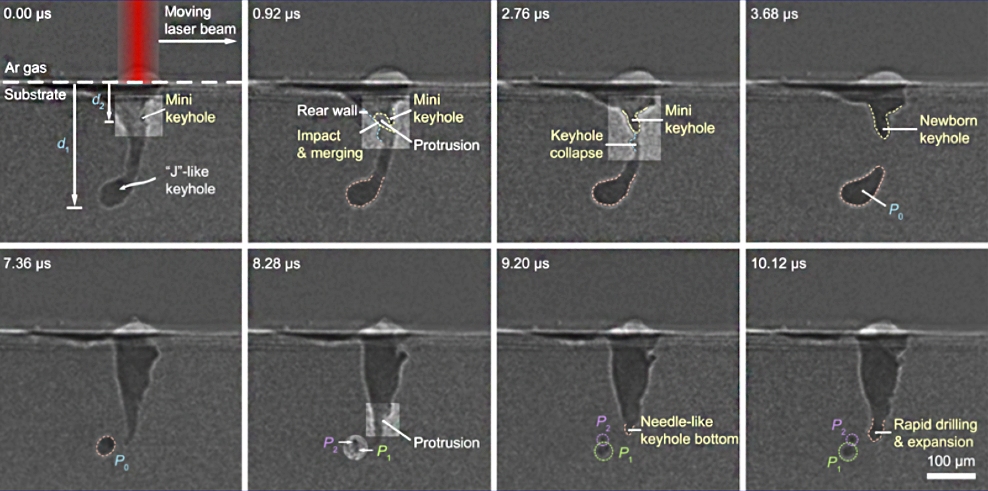

“Laser powder bed fusion is a dominant additive manufacturing technology that has yet to reach its potential,” writes the author, Sherry Stokes. “The problem facing industry is that tiny bubbles or pores sometimes form during the printing process, and these pores create weak spots in finished products.” Building on previous research that quantified the keyhole phenomenon , the research team used extremely bright high-energy x-ray imagining to watch instabilities of the keyhole. Pores form during fluctuations of the keyhole, and it changes its shape: the keyhole tip morphs into a “J” shape and pinches off. This unstable behavior generates acoustic waves in the liquid metal that force the pores away from the keyhole so that they survive long […]

Click here to view original web page at www.thefabricator.com

0 Comments