In David Noble’s book, Forces of Production: A Social History of Industrial Automation, the late York University professor examined the history of machine tool automation in the U.S. Noble argues that computerized numerical control (CNC), was the result of social and political forces that pushed for greater automation in manufacturing so that large corporations, particularly those in the aerospace and weapons industries, could maintain leverage over union members on the factory floor.

.

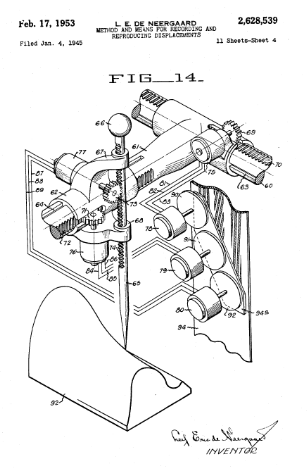

While Noble makes his argument and relays the history of CNC, he touches briefly on a technology that has become otherwise lost from manufacturing history. Invented by Lloyd B. Sponaugle and Leif Eric de Neergaard at the end of World War Two, it was called “record-playback” or the “motional” method for programming machine tools.

.

How it worked was that a machine operator would fabricate a part or trace a template of the part and the system would record the operator’s motions onto magnetic or punched tape. The tape could then be fed into a piece of manufacturing equipment, like a lathe, and the motions would be replayed, just as the machine operator had performed them, producing an identical part.

.

The technology got far enough that multiple patents were filed for it and working systems were developed, including within GE, which sought machine tool automation due to a number of large strikes that had recently occurred at its Schenectady, New York headquarters. In 1946, two engineers from GE’s Industrial Control Division, Lowell Holmes and Lawrence Peaslee, followed in the footsteps of Leif Eric de Neergaard, “recording and reproducing displacements (registered as shifts in the phase of electrical signals).” The initial system featured a selsyn generator, with which the angular movement was transmitted to a motor that moved an odometer counter and a wire recorder.

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments