Researchers from the Czech Republic and Brazil have come together to highlight ultrasonic testing for stress analysis in ‘ Residual stress analysis of additive manufacturing of metallic parts using ultrasonic waves: State of the art review .’

.

Residual stresses (RS) are still a notorious problem in metal 3D printing, with the rapid heating and cooling resulting in potentially numerous defects, part failure and even damage to an additive manufacturing (AM) machine. Other factors also come into play such as grain size, porosity, voids, shape or structure, supports, and processing parameters.

.

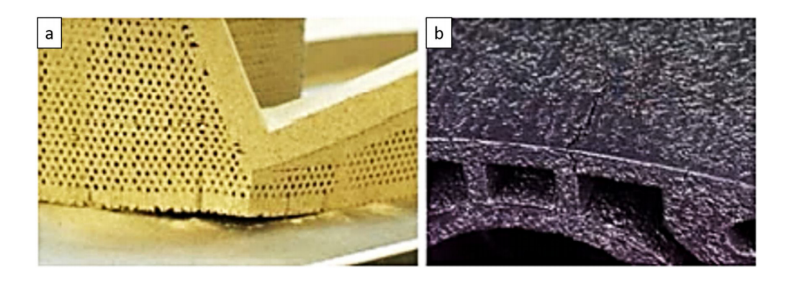

In turn, RS can cause the following issues in printed parts: Deformation Poor fatigue resistance Critical failure during operation Lower chemical resistance Lower magnetization Decreased strength Direct consequences of residual stresses in AM parts – (a) distortion and separation from the base plate; (b) crack formation [10]. For these reasons, a number of methods are being used to avoid […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments