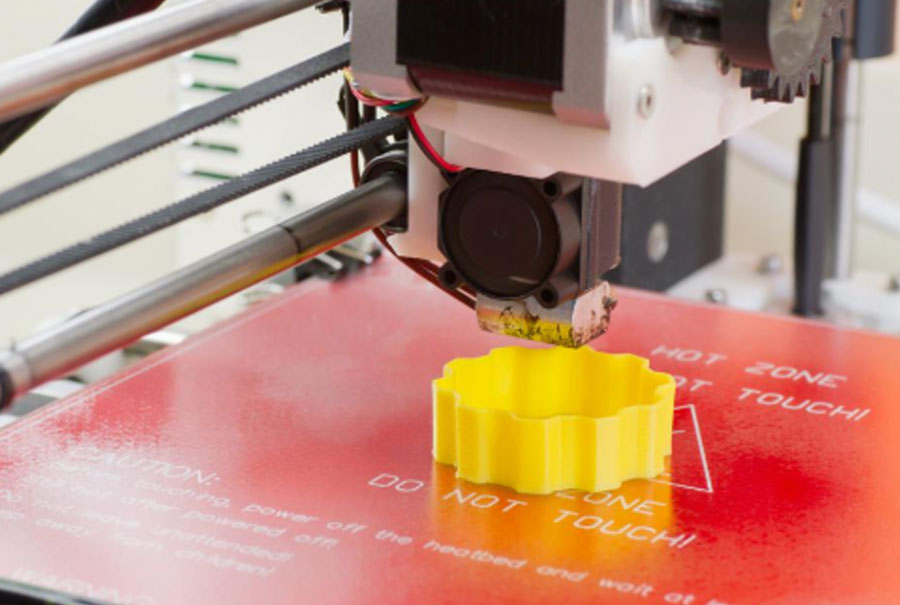

The use of 3D CAD (computer aided design) in fast fabrications of physical parts, models or assemblies is known as rapid prototyping. Using additive manufacturing, or 3D printing as it is better known, completes the parts’, models’ or assemblies’ creation process.

.

A prototype is said to be one of high fidelity if the intended finished product is a close match to the design, as contrasted to a prototype with remarkable difference with the finished product which is termed a product with low fidelity.

.

Processes Involved

.

In Rapid prototyping, a number of technologies are involved. The most common of these technologies is an additive manufacturing that employs layering. Beyond this are other technologies which include high-speed machining, molding, casting and extruding. Although the most commonplace process of rapid prototyping is additive manufacturing, prototypes have equally been created by other very conventional […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments