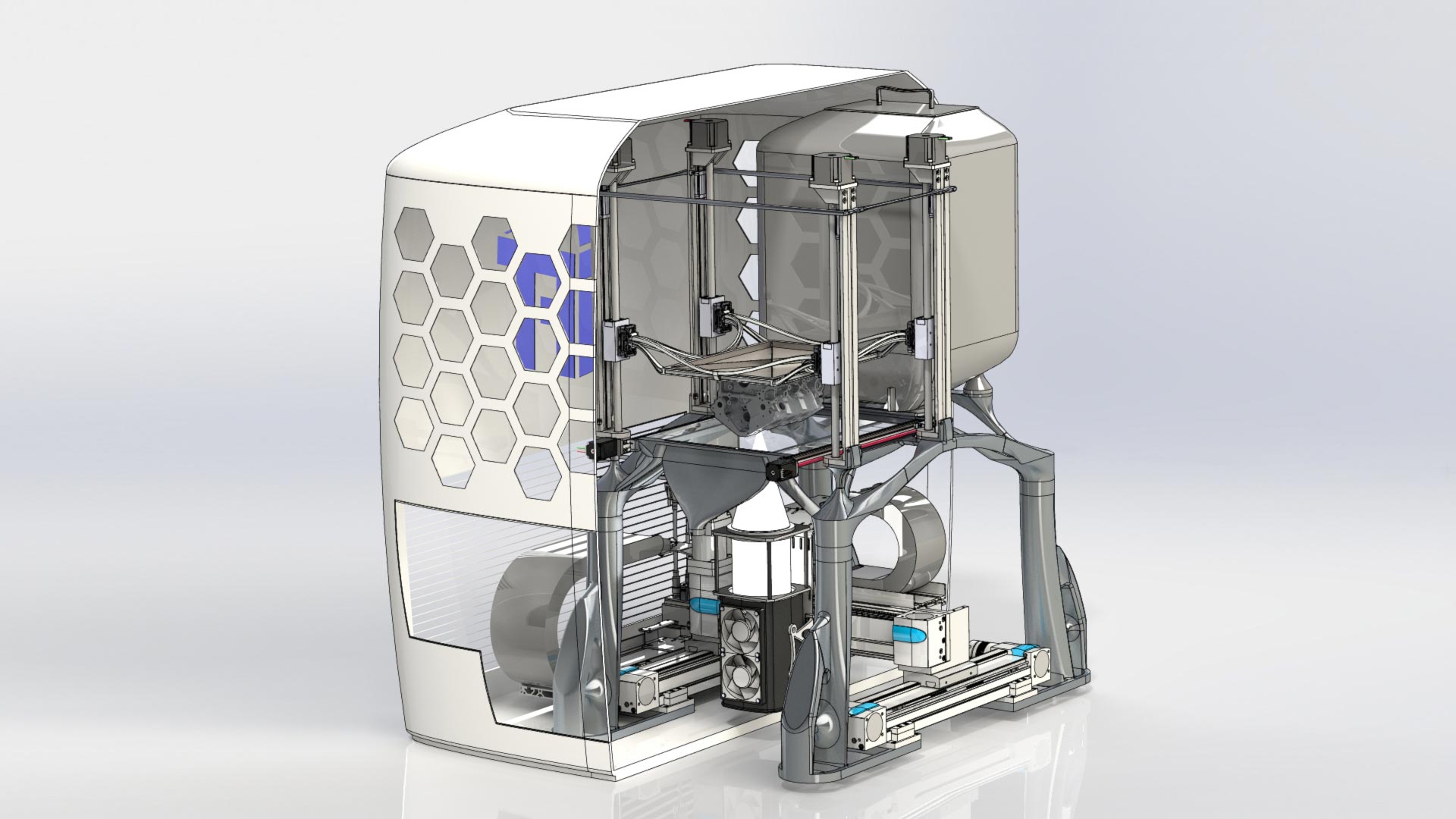

The 3D printer developed at TU Graz melts metal powder using high-performance LED light sources and then processes it into components in additive manufacturing.

.

Selective LED-based melting (SLEDM) — i.e. the targeted melting of metal powder using high-power LED light sources — is the name of the new technology that a team led by Franz Haas, head of the Institute of Production Engineering at TU Graz, has developed for 3D metal printing and has now applied for a patent.

.

The technology is similar to selective laser melting (SLM) and electron beam melting (EBM), in which metal powder is melted by means of a laser or electron beam and built up into a component layer by layer. However, SLEDM solves two central problems of these powder bed-based manufacturing processes: the time-consuming production of large-volume metal components and the time-consuming […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments