Wind off the coasts of the U.S. could be used to generate more than double the combined electricity capacity of all the nation’s electric power plants, reports have suggested.

.

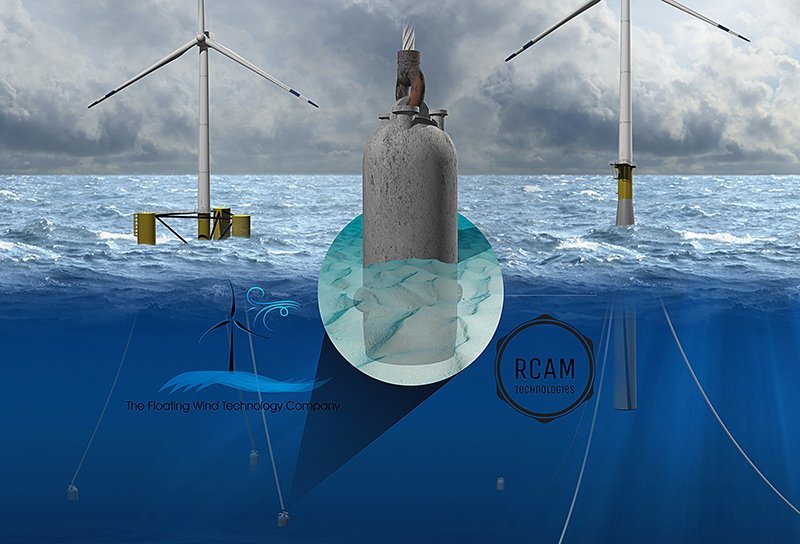

But building wind turbines offshore is expensive, requiring parts to be shipped at least 30 miles away from a coast. Purdue University engineers are conducting research on a way to make these parts out of 3D-printed concrete, a less expensive material that would also allow parts to float to a site from an onshore plant.

.

“One of the current materials used to manufacture anchors for floating wind turbines is steel,” said Pablo Zavattieri , a professor in Purdue’s Lyles School of Civil Engineering . “However, finished steel structures are much more expensive than […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments