For next generation photonics, sensing and imaging technologies, the ability to 3D print glass is critical to developing highly complex, freeform, or small-scale structures. Yet it has proven difficult to 3D print glass, which has a high melting point over 1400°C, while also retaining its unique chemical, mechanical and optical properties.

.

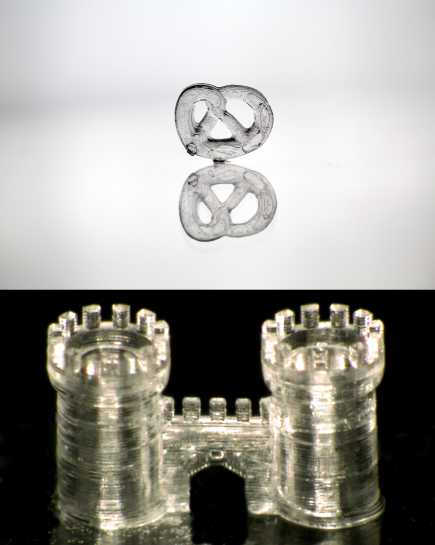

Recent advances have not only resulted in the successful 3D printing of glass, with properties and shape identical to that of commercial glass, but also in further developing specific 3D printing technologies to print glass structures at the scale and complexity never possible before— and with customizable optical properties. One of these is OptoGlass3D , a novel method of 3D printing glass developed by Glassomer GmbH and Nanoscribe GmbH , and led by Professor Bastian Rapp of the University of Freiburg and Head of NeptunLab . Images courtesy of KIT, NeptunLab The OptoGlass3D project is funded with a […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments