“For sale: a new ranch-style, 130 square meter house located in Long Island, New York. Three bedrooms, living room, open kitchen, two bathrooms, garage. Starting price: $300,000. Special feature: it will be the first 3D-printed house sold in the United States.”

.

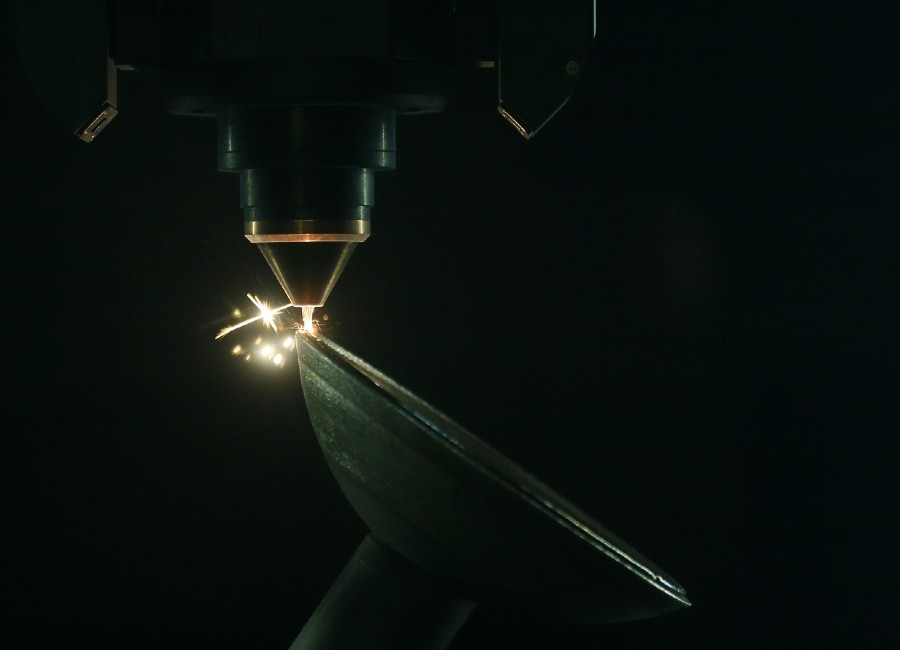

Since the ad appeared in February , Kirk Andersen’s phone has been ringing off the hook: SQ4D, the start-up he runs, has developed the 3D-printing technology that will get this house off the ground in a few weeks… if the construction goes as planned. 3D-printer XXL version SQ4D is not new to this. At the end of 2019, the 12-person company printed its first building that serves as a model house. “We printed the entire wall in 48 hours,” says Kirk Andersen. “We used that to test our technology, and also to get all the approvals so we could sell the next house. This all took over a year because of the COVID-19 crisis.” SQ4D’s technology resembles an XXL version of the most common 3D-printers. On a large gantry circulates a print head whose movements, controlled by computer, follow the plan of the house. With each pass, a nozzle deposits a layer of concrete of about two centimeters. […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments