A cut above desktop systems, the pro market was always aimed at the sophisticated designer or consumer and small businesses.

.

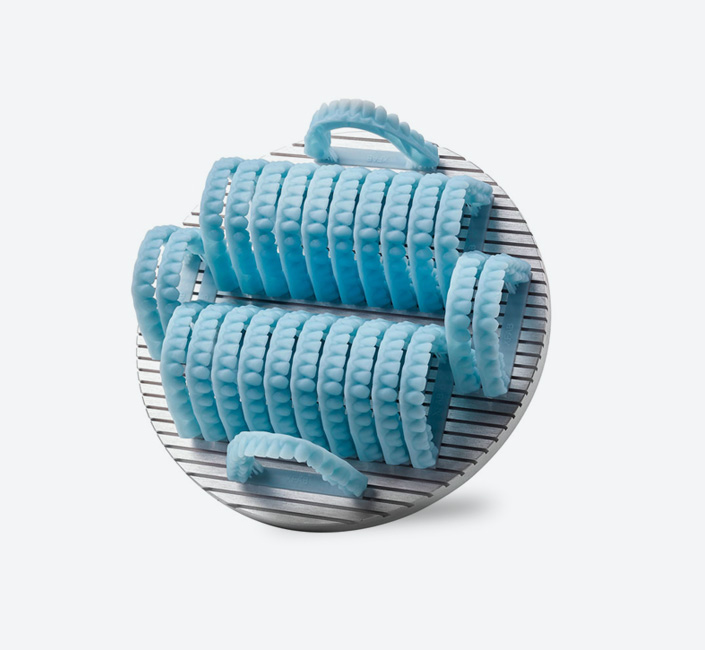

Increasingly, these systems are used for production in casual, series and volume manufacturing. Through prototypes, they are continually used by businesses, as well. They are used to make molds, lost wax casts for jewelry, dental parts, and hearing aids. Good at lots of tiny small smooth parts, these systems are finding their niche as a real productivity and manufacturing tool. At the same time, many are used by designers working from home or consumers that wish to explore more detailed, smoother prints. Custom jewelry shops and designers making small series of goods also use these systems a great deal. Slicker in design and software than material extrusion (FFF/FDM) systems, they do appeal to a different market, but plenty of businesses run both FDM and SLA. Support removal is a chore and resin prices are elevated when compared to other 3D printing materials, but these systems are not toys. They play a part of people’s businesses and are judged as such. Whereas, OEMs often claim that these systems can print end-use parts, this is often not done. On the whole, […]

A Perfect Pair: 3D Printed Drones

Drones bring great energy to the design and 3D printing realm, with engineers engaged in developing new technology...

0 Comments