A few years ago, the R&D director of Torus Group set himself the challenge of making 3D printing an indispensable part of the bespoke metrology business by exploring its benefits for all aspects of day-to-day operations.

If the fact that Torus now prints its own doorstops and whiteboard erasers is anything to go by, he may have surprised even himself.

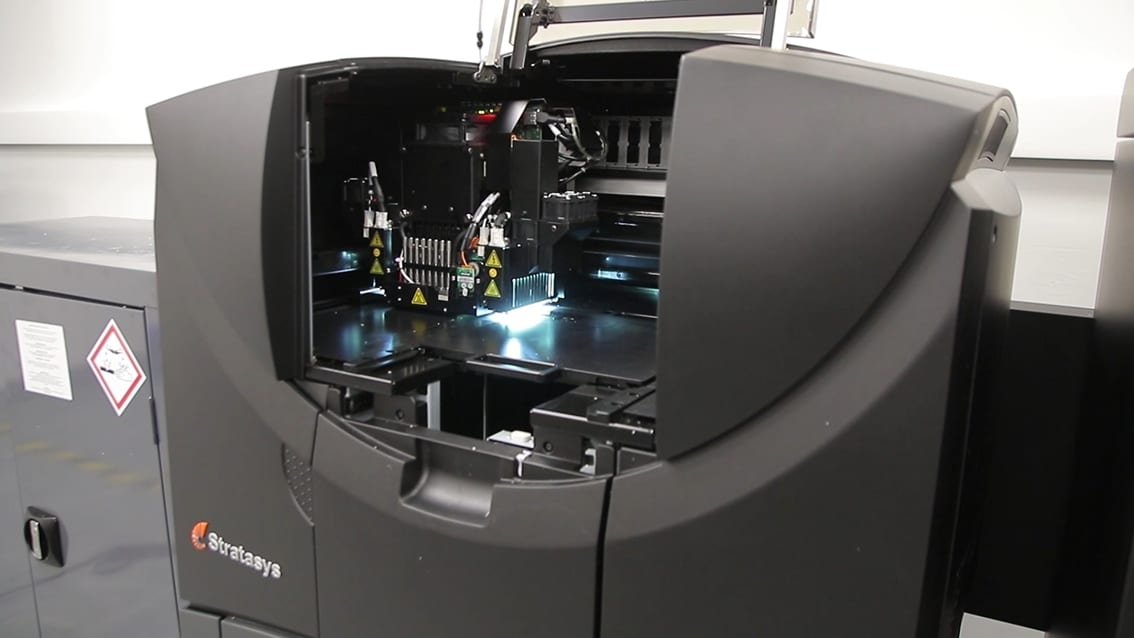

The greatest achievement of the company’s additive manufacturing adventure so far, however, is the development of a unique part that is helping to better meet the stringent demands of internationally renowned clients. After experiencing problems with reliability and functionality in the past, Torus looked at how it might use 3D printing to redesign and recreate the filling assembly on its top load and volume gauge machine.

The assembly is a complex construction of channels, inserts and electrodes that allow water to flow in and out […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments