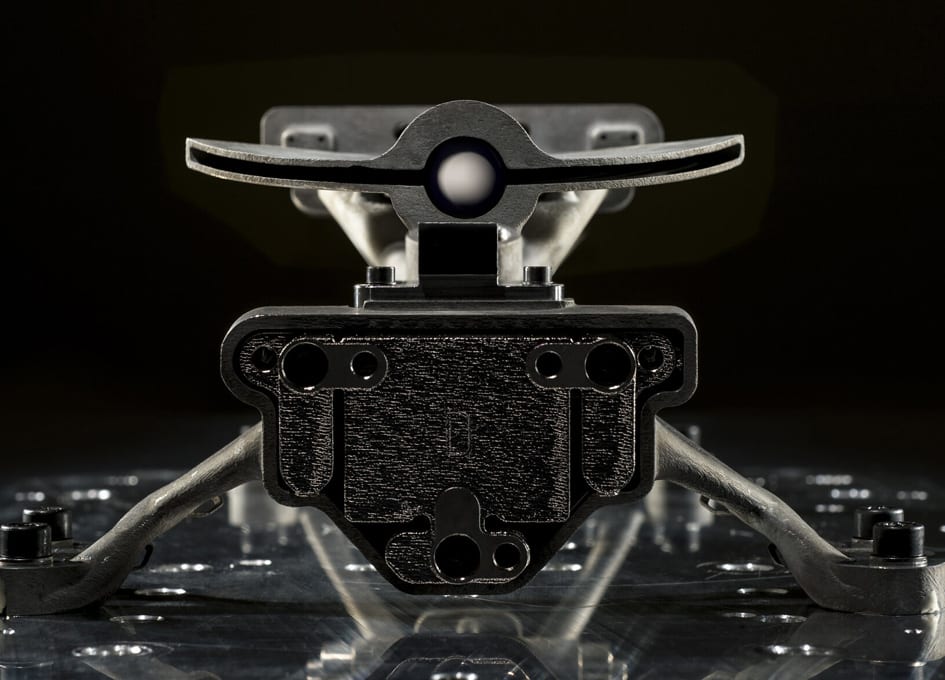

This weirdly organic item is the answer to an engineering question: how to take the maximum benefit from 3D printing to produce a highly demanding item for a space mission?

.

An ESA-led team began with a Dutch-designed space telescope which identifies ozone and other trace gases in Earth’s atmosphere, then comprehensively redesigned it for manufacture in this innovative way. The result is made out of three main parts, with nine parts altogether including the telescope’s two mirrors, printed in flight-grade aluminium alloy.

.

Compared to the 2.8 kg original version, the telescope of the Ozone Monitoring Instrument, OMI, flown aboard NASA’s EOS-Aura mission, this version is 0.76 kg, some 73% lighter, with no reduction in measurement quality. “This is a high performing instrument – the predecessor of the Tropomi instrument aboard Sentinel-5P – that needs to be extremely precisely […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments