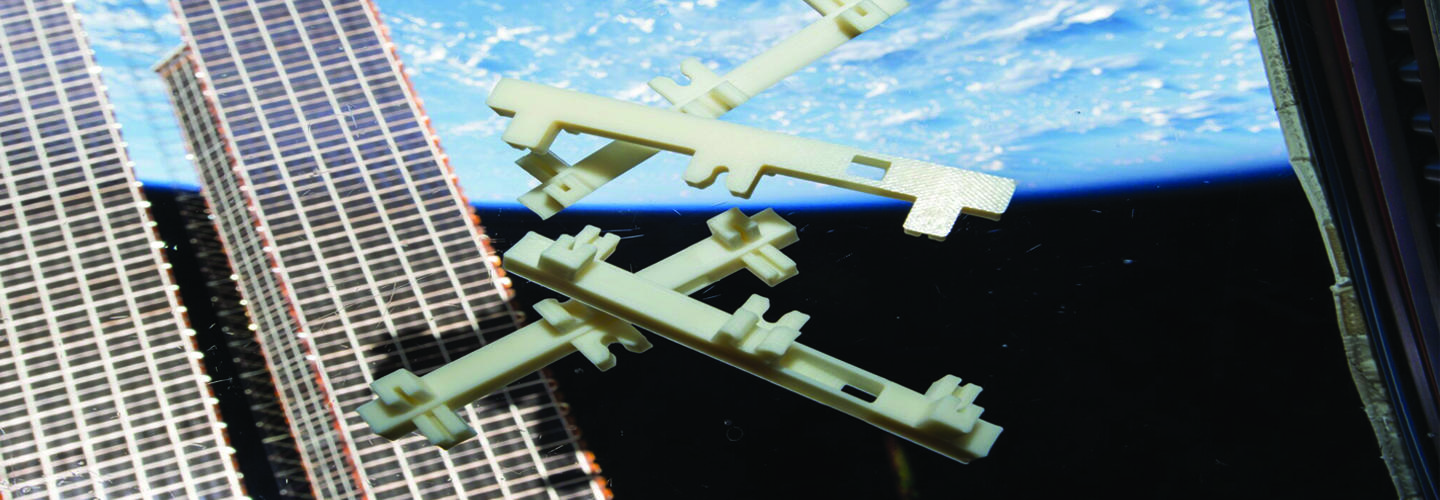

These white rails, the rigid skeletons of small CubeSats, were the first objects 3D printed in orbit and used as part of a functioning satellite. NASA’s 3D-printing program began with making tiny wrenches and may end up building infrastructure on the moon.

.

In between those moments, however, astronauts aboard the International Space Station are testing technology designed to make the printing process more efficient. The space station is currently home to two 3D printers, one known as the Refabricator and another called the Additive Manufacturing Facility (AMF).

.

A third device, the Recycler, is designed to recycle used material to save room and weight on the ISS, much like the Refabricator. Each works in a slightly different way, and astronauts are trying to determine which works best. In addition to basics such as tools and small parts, NASA hopes that eventually the 3D printers will be able to print […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments