Velo3D announced today that it has launched the new Sapphire XC metal 3D printing system. The company states that it already has 13 advanced orders for the machine, touting a 75% reduction in cost per part and 500% increase in throughput when compared to the previous Sapphire.

.

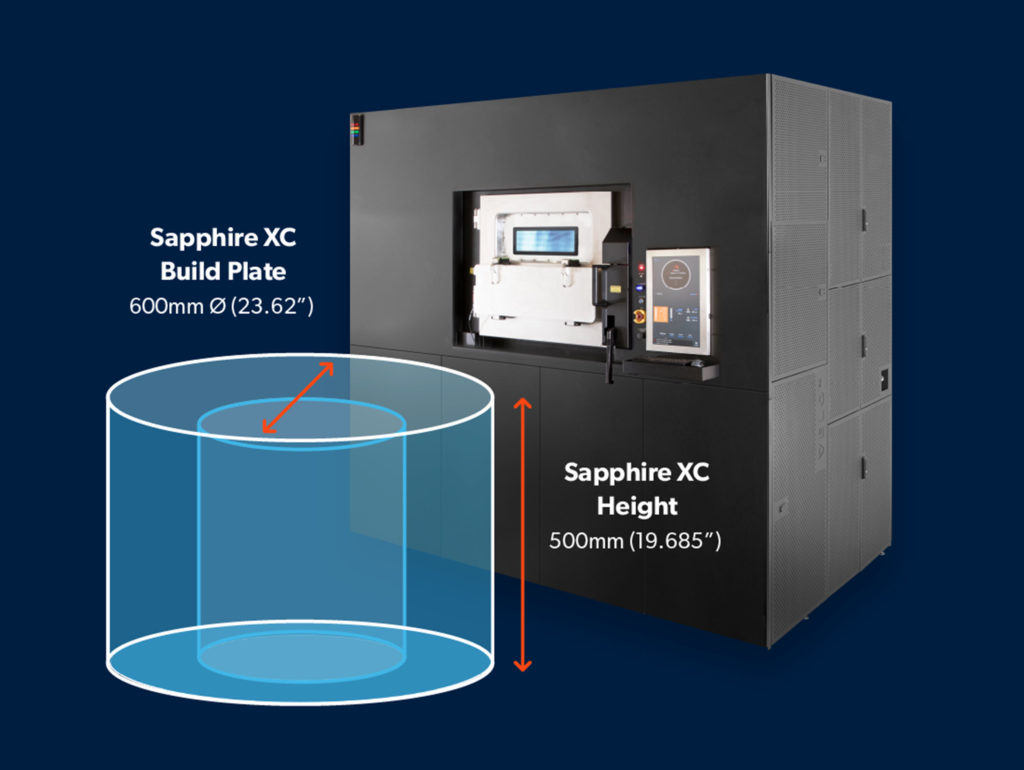

To achieve these rates, the Sapphire XC features a 600mm x 550 mm build volume and eight 1,000W lasers. General machine deliveries of new systems will start Q1 2022, as the company will be busy manufacturing and delivering systems already ordered until then.

.

Of the new product, Benny Buller, founder, and CEO of Velo3D, said: “Printing larger parts without the additive manufacturing constraints of support structures is highly attractive to many industrial end-users. For the first time, customers will be able to 3D-print uncompromised geometries, with the highest confidence in part quality, in a large format system. Quality assurance with large scale […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments