Most custom plastic parts are produced commercially via injection molding. This is because once the upfront costs are covered, injection molding can produce in quantities of thousands to hundreds of thousands with very low price points per item. However, those upfront costs can drive decisions on when to use injection molding, especially if the quantities needed for production are not very high.

.

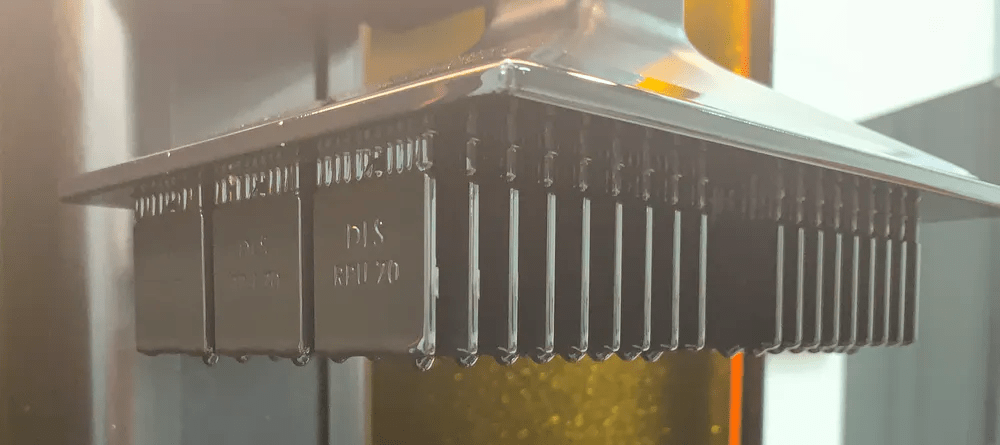

This is where 3D printing can have an advantage for production. 3D printers can make a part without the need for upfront tooling costs. Sometimes called direct digital manufacturing, a 3D printing service only requires a 3D CAD file to get started. With a low barrier to entry both in costs and minimum requirements, 3D printing can help everywhere from rapid prototyping to low volume production. 3D printing often has a break-even between 250 and 2,000 parts before injection molding becomes a more viable option. 3D printing […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments