As you would expect, each generation of rover sent to Mars by NASA’s Jet Propulsion Laboratory (JPL) has been considerably more sophisticated than its predecessors. From the trolley-like Sojourner to Opportunity , Spirit , and Curiosity , rovers over the past 20 years have grown not only in capability but have advanced significantly in terms of manufacturing techniques.

.

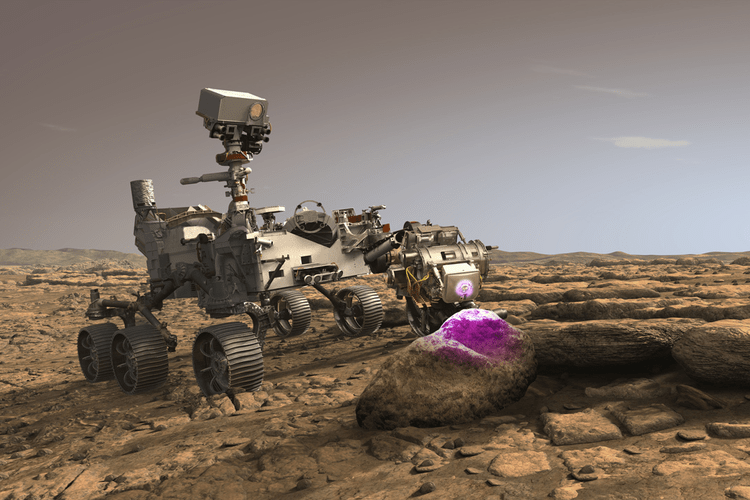

Now, the next rover to land on Mars includes 11 metal parts made with 3D printing, otherwise known as additive manufacturing. NASA’s car-sized Perseverance rover is due to land on the red planet on February 18, 2021. Its primary purpose is astrobiology, or the search for fossilized microbial life. Perseverance will collect and “cache” samples of Martian regolith for future pickup by NASA/European Space Agency spacecraft. But with the help of some sophisticated 3D-printed parts, Earth’s latest ambassador to Mars is capable of a lot more.

.

Which Parts of Perseverance Are 3D-printed? The 11 3D-printed parts are all found within […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments