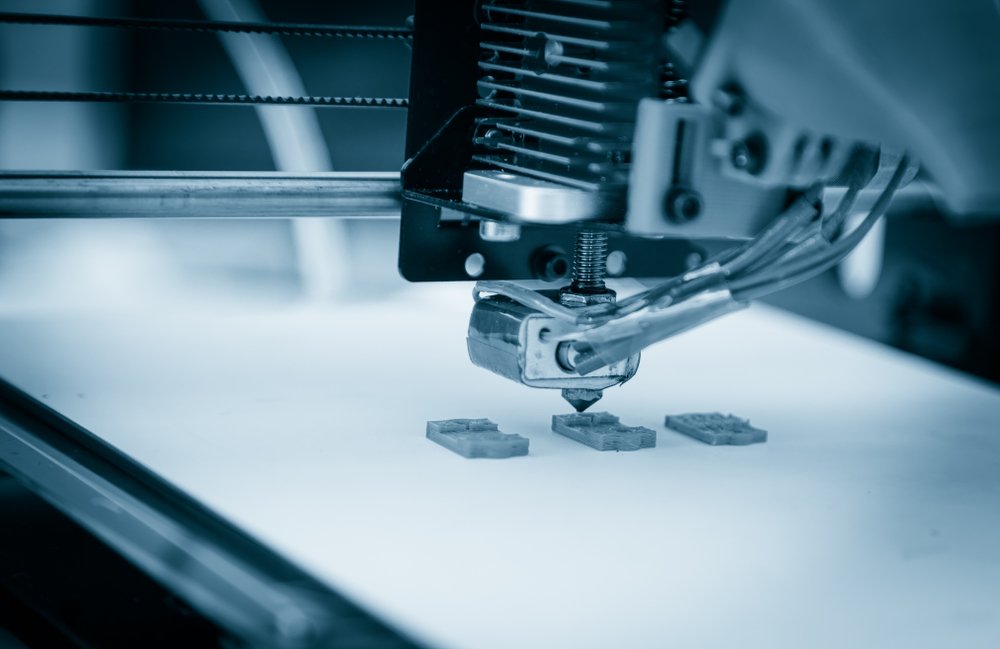

The outlook for additive manufacturing and 3D printing is promising. Back in 2017, Thomas reported on the increased sourcing activity for additive manufacturing. Although the base technology of additive manufacturing was developed in the 1980s, its use has become more prevalent in the last few years as advancements grow and prices drop. Sourcing activity sessions for additive manufacturing systems in 2020 was up 37.8% compared to 2019. And according to Statista, the global market for 3D printing and services is expected to grow to almost 50 billion U.S. dollars by 2025.

.

Opportunities and Advantages of Additive Manufacturing Early adopters used additive manufacturing technology to speed prototyping and help in reverse engineering parts. This technique has become a staple in many custom metal, and plastic fabrication businesses as designers gain more experience with the additive manufacturing process. Flexibility For Time To Market And Product Differentiation Additive manufacturing technology now sees increased adoption beyond prototyping into end and spare part production because it offers complexity and performance advantages that are not possible with conventional methods, traditional machining, or molding processes. Testing performed by NASA in 2013 led engineers to believe additive manufacturing-produced fuel injectors were a viable technology for final […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments