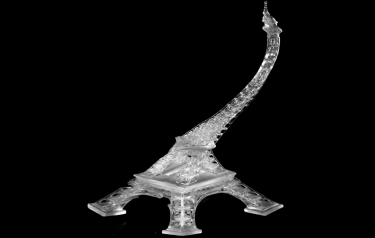

Engineers have developed a new method that uses light and robotics to improve 3D printing speed and precision, whilst providing the freedom to move, rotate or dilate each layer.

.

The speed of light has come to 3D printing. Northwestern University engineers have developed a new method that uses light to improve 3D printing speed and precision while also, in combination with a high-precision robot arm, providing the freedom to move, rotate or dilate each layer as the structure is being built.

.

Most conventional 3D printing processes rely on replicating a digital design model that is sliced into layers, with the layers printed and assembled upwards like a cake. The Northwestern method introduces the ability to manipulate the original design layer by layer and pivot the printing direction without recreating the model. This “on-the-fly” feature enables the printing of more complicated structures and significantly improves manufacturing flexibility. “The 3D printing process is no longer a way to merely make a replica of the designed model,” said Cheng Sun, Associate Professor of mechanical engineering […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments