Last Friday, French astronaut Thomas Pescet flew for the second time to the International Space Station (ISS) for a 6-month flight. In doing so, he becomes the first French captain of the International Space Station. And if we’re talking about that today, it’s because it’s shipped with 3D printed parts, in particular packaging for Meals provided by the Hanaf group, as well as a protective bag for the French astronaut sleeping squad.

.

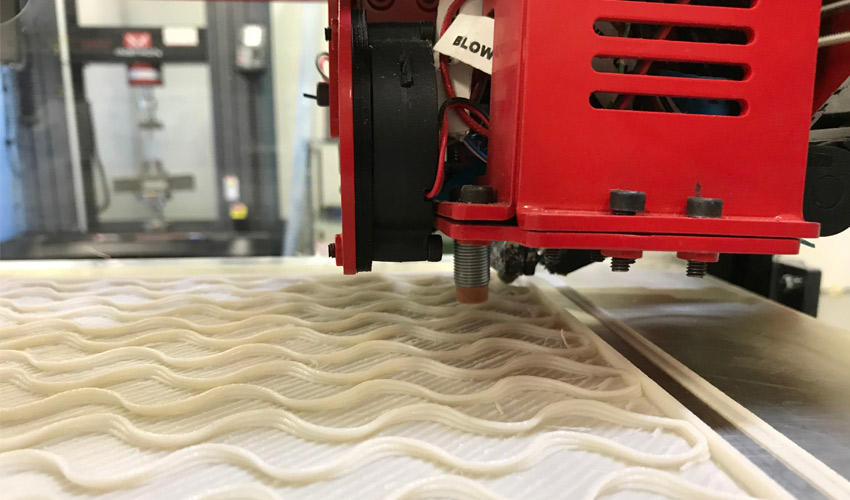

These parts are designed from Recyclable and edible foam , Based on PHA, is a polymer of natural origin made by bacteria. These foams, designed with the ComposiTIC technology platform, provide high protection, isolating shock and vibration. The ComposiTIC technology platform was established in 2014 at the University of South Brittany (UBS). Its goal is to develop Vehicles Innovative thanks to robotic fiber placement technology. The platform was ordered by CNES as part of Thomas Pesquet’s ESA Alpha mission. Over the next six months, the French engineer must do several maintenance as well as a hundred scientific experiments aboard the International Space Station. Additive manufacturing has been called for. These are PHA pellets that have been transformed into filament for 3D part printing (Image credits: UBS) 3D […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments