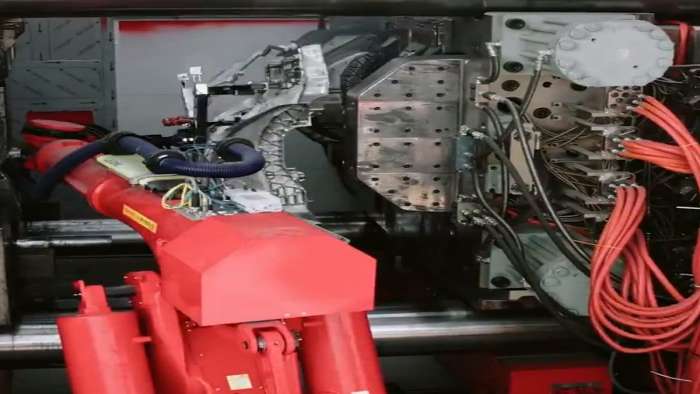

The die casting machine takes a special molten material that is proprietary to Tesla and forms it into the exact shape for the piece of the car Tesla needs. It’s like “3D printing” the portion of the car as its formed into the exact shape that Tesla needs! T

.

he die casting machine forces a molten metal alloy (a metal alloy Tesla created that is special for just Tesla) into a reusable mold. This mold is then opened and the now solidified piece is cooled and cleaned by robots and made ready for use. Quality checks are also performed on the solidified metal. Each fresh piece from start to finish takes 1-2 minutes and equals about 1,000 castings a day per machine! It’s basically making real-life full-sized cars just like a toy car is made! This video from 1965 is the same kind of concept! Who makes the die casting machine? The die casting machines are made by the […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments