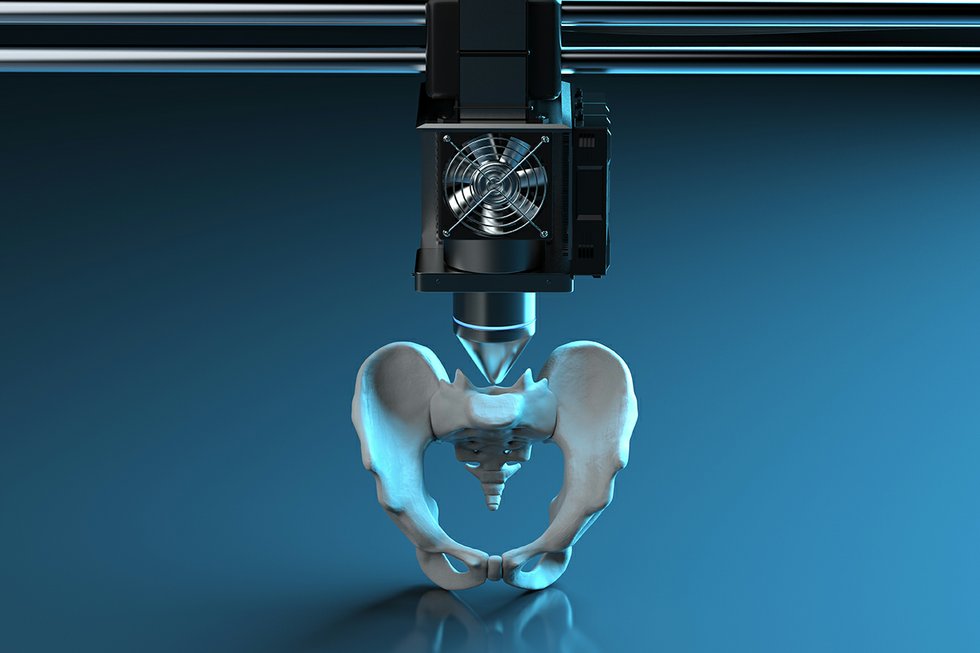

Glaze Prosthetics is bringing its prosthetic arm production process in-house after investing in HP’s Multi Jet Fusion 580 Colour 3D printing system. The company, which was founded in 2017, allows its patients to choose the model, colour and finish of their prosthetics – as well as design and order them online – and believes that investing in its own 3D printer will help to speed up lead times.

.

Previously, Glaze has leant on an external service provider using an HP Multi Jet Fusion 4200 machine. By adopting the Multi Jet Fusion 580 Colour system, Glaze has been able to upload patient scan data to its database, send the information directly to the printer and print the prosthetic in the right shape, size and base colour. Additional details still need to be painted on by hand but being able to print the base colour has significantly reduced the time it takes to develop the products, with Glaze now able to produce and deliver customised prosthetics within 7-14 days. Investing in the Multi Jet Fusion 580 Colour system, Glaze says, has allowed the company to drastically reduce staff costs and time, as well as achieve fine detail and high dimensional accuracy. […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments